- English

- Search

- English

Titanium FAQ

Is titanium a metal?

A hard, shiny and strong metal. Titanium is as strong as steel but much less dense. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron.

What is Titanium used for?

Titanium is as strong as steel but much less dense. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron. These alloys are mainly used in aircraft, spacecraft and missiles because of their low density and ability to withstand extremes of temperature. They are also used in golf clubs, laptops, bicycle frames and crutches, jewellery, prosthetics, tennis rackets, goalie masks, scissors, surgical tools, mobile phones and other high-performance products.

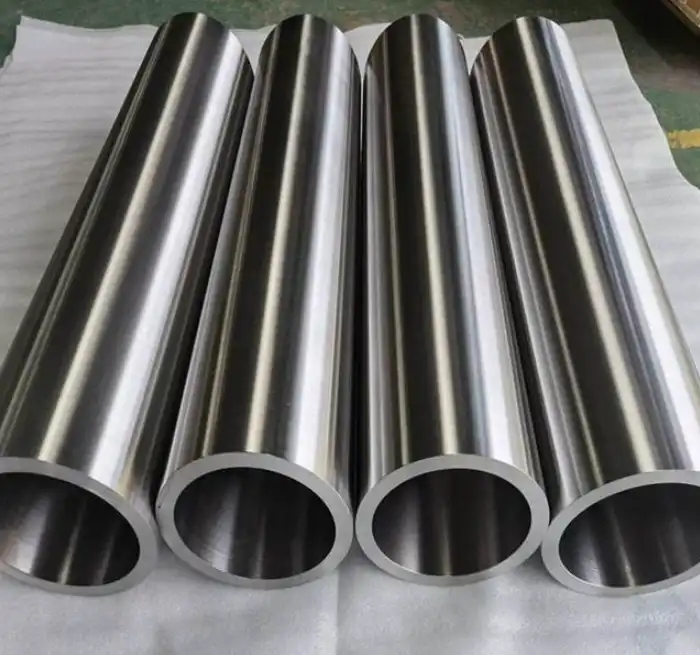

Power plant condensers use titanium pipes because of their resistance to corrosion. Because titanium has excellent resistance to corrosion in seawater, it is used in desalination plants and to protect the hulls of ships, submarines and other structures exposed to seawater.

Titanium metal connects well with bone, so it has found surgical applications such as in joint replacements (especially hip joints) and tooth implants.

The largest use of titanium is in the form of titanium(IV) oxide. It is extensively used as a pigment in house paint, artists’ paint, plastics, enamels and paper. It is a bright white pigment with excellent covering power. It is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility.

Titanium(IV) oxide is used in sunscreens because it prevents UV light from reaching the skin. Nanoparticles of titanium(IV) oxide appear invisible when applied to the skin.

What is Alloyed Titanium?

Titanium alloys are metals that contain a mixture of titanium and other chemical elements. For most applications, it is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, and for some, it is also alloyed with palladium. Such alloys have very high tensile strength and toughness, they are light in weight, have corrosion resistance and have the ability to withstand high temperatures. The heat resistance enables a heat treatment process after the alloy has been worked into its final shape but before it is put to use, allowing much easier fabrication of a high-strength product.

What is Commercially Pure Titanium?

Commercially Pure Titanium is represented by four distinct grades, specifically grade 1, grade 2, grade 3 and grade 4. Pure titanium ranges from grade 1, which has the highest corrosion resistance, formability and lowest strength, to grade 4, which offers the highest strength and moderate formability.

Dose Titanium get rusty?

Pure titanium is resistant to rusting and corrosion from liquids including chemicals, acids, and saltwater as well as various gases because of its oxide barrier. As the name oxide implies, oxygen is needed to produce this barrier.