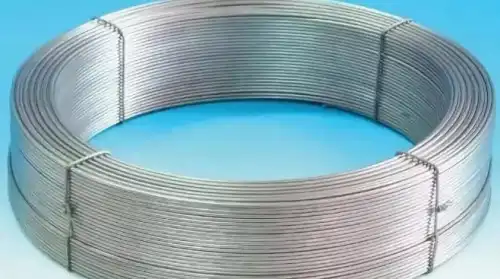

As an indispensable material in modern industry, titanium alloy wire has a wide range of applications, covering key areas such as aviation fasteners, consumer electronics (3C products), eyeglass frames, automotive parts, medical equipment, and welding materials. To achieve high-precision and high-performance wire products, the cold drawing process has become an important process, especially when the wire diameter needs to be 30%-40% larger than the final product. This article will deeply explore several key factors and optimization strategies that affect the drawing performance of titanium alloy wire.

1. Strict control of raw material quality

Chemical composition: The chemical composition of titanium alloy directly affects its physical and mechanical properties. It is very important to strictly control the content of elements such as H, O, N, Fe, and Si. For example, the H element is prone to hydrogen embrittlement and needs to be strictly monitored and controlled within a safe range.

Surface quality: There must be no defects such as cracks, folds, or scars on the surface of the raw material. These defects may expand during the drawing process, resulting in reduced strength or even fracture. Therefore, the raw materials need to undergo strict surface inspection and pretreatment to ensure a smooth and defect-free surface.

2. Optimization of the heat treatment process

Heat treatment plays a vital role in the drawing process of titanium alloy wire. Annealing treatment (including pretreatment annealing, intermediate annealing, and finished annealing) aims to reduce work hardening, improve the elongation and plasticity of the material, and create favorable conditions for the subsequent drawing process. A reasonable annealing system can effectively improve the organizational structure of the material and improve the drawing performance.

3. Selection and design of drawing dies

Die material: Drawing dies are often made of cemented carbide (such as YK6, and YK8) and diamond. Cemented carbide is widely used for its high hardness and good wear resistance, while diamond drawing dies are the first choice for fine and ultra-fine wire drawing due to their extremely high hardness and wear resistance, although they are expensive and difficult to process.

Die design: The design of the die needs to be adjusted according to the wire specifications and drawing requirements. Common die shapes include arc-shaped dies and conical dies, which are suitable for wires of different diameters. The design of the die hole also needs to be carefully considered, including the inlet cone, working cone, sizing belt, and outlet cone, to ensure that the wire is deformed smoothly and the quality is stable during the drawing process.

4. Fine control of drawing process parameters

Deformation per pass: The room temperature tensile plasticity of titanium alloy is low, so the deformation per pass needs to be reasonably controlled to avoid excessive wire breakage. By gradually increasing the deformation, the organizational structure of the material is gradually improved and the tensile strength is improved.

Total deformation: The increase in total deformation will increase the strength of titanium alloy wire, but it will also aggravate work hardening and reduce toughness. Therefore, it is necessary to balance the relationship between strength and toughness according to specific needs to determine the optimal total deformation.

Drawing speed: Drawing speed is one of the key factors affecting the performance of titanium alloy wire. Increasing the drawing speed can improve production efficiency and save energy, but it is necessary to ensure the wire's quality and the drawing process'sstability. By adjusting the drawing speed, the deformation behavior and microstructure of the material can be optimized.

The titanium alloy wire drawing process involves the fine control and optimization of multiple key factors. By strictly controlling the quality of raw materials, optimizing the heat treatment process, selecting suitable drawing dies, and fine-tuning the drawing process parameters, the performance and quality of titanium alloy wire can be significantly improved to meet the application needs of various fields.