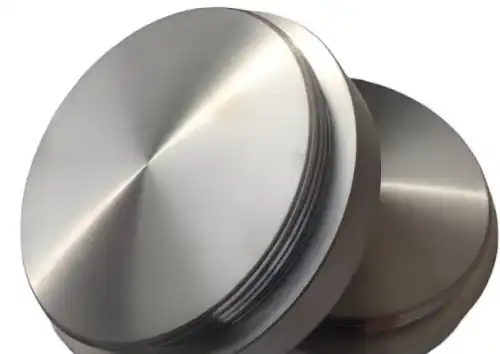

Titanium metal materials are widely used in aerospace, medical, chemical, and other fields due to their high strength, low density, good corrosion resistance, and high-temperature resistance. In the processing of titanium metal. By applying an external force to make the material plastically deform, it changes its size, and shape and improves the material's performance. This article will introduce the forging technology in titanium material processing in detail, including different types of forging methods and their characteristics.

1. Classification of forging methods

Free forging: Free forging is the most basic forging method. The blank is deformed freely between the upper and lower anvils. This method is suitable for producing forgings with simple shapes and low precision requirements, such as large gears and shafts. The advantages of free forging are a flexible process and strong adaptability, but the material utilization rate is low, and higher forging skills are required.

Die forging: Die forging is a method of forging the blank in a die. According to the opening and closing of the die, die forging can be divided into open die forging and closed die forging. Closed die forging is suitable for producing large batches of forgings with complex shapes because it has no flash, a high material utilization rate, and high dimensional accuracy of forgings. The advantages of die forging are high production efficiency and good titanium materials forging quality, but the die cost is high, and regular maintenance is required.

Extrusion: Extrusion is a method of placing the billet into the extrusion cylinder, applying pressure to the billet through the die and extrusion rod, and extruding it from the die hole. Extrusion is suitable for producing forgings such as long strips, pipes, and profiles. The advantages of extrusion are a high material utilization rate and dense internal structure of forgings, but the equipment investment is large and the process is complex.

Roll forging and cross-rolling: These two methods are mainly used to process slender materials, and the billet is continuously deformed by rotating rollers or rollers. The advantages of roll forging and cross-rolling are high production efficiency, good material utilization rate, and are suitable for large-scale production.

Swing rolling, swing forging, and ring rolling: These methods use rotating dies to partially or completely shape the billet. They are suitable for producing forgings with complex shapes and high precision requirements, such as gears, bearing rings, etc. These forging methods usually require precise die design and control to achieve high-quality products.

2. Key points of the forging process

Choice of forging ratio: A reasonable forging ratio is crucial to improving the quality of forgings and reducing costs. A forging ratio that is too small may lead to uneven internal structure of forgings and reduced performance; a forging ratio that is too large may increase the difficulty and cost of forging.

Heating temperature and holding time: The forging of titanium materials needs to be heated before forging to improve its plasticity and reduce deformation resistance. The correct heating temperature and holding time can ensure uniform temperature inside the billet and avoid overheating or overburning.

Deformation amount and deformation speed: Reasonable deformation amount and deformation speed have an important influence on controlling the structure and performance of forgings. Excessive deformation may cause cracking or uneven deformation of forgings; too fast deformation speed may cause residual stress inside forgings.

Die design and maintenance: The design quality of the die directly affects the forming accuracy and surface quality of the forging. The die should have high strength and hardness to withstand the high temperature and high pressure during the forging process. At the same time, regular maintenance and inspection of the mold is also an important measure to ensure the quality of forgings.

The forging of titanium materials is a complex and delicate process. By selecting the appropriate forging method, optimizing the forging process parameters, designing a reasonable mold, and strengthening process control, high-quality and high-performance titanium forgings can be produced. With the continuous advancement of science and technology and the continuous improvement of process technology, the forging of titanium materials will play an important role in more fields.