In recent years, titanium, a lightweight and high-strength material, has shown great application potential in the automotive industry. Its unique physical and chemical properties have brought revolutionary changes to automobile manufacturing and become an important force in promoting the development of the automotive industry.

Excellent mechanical properties

Titanium stands out among lightweight metal materials for automobiles for its high strength and high-temperature resistance. Compared with aluminum and stainless steel, titanium can still maintain good mechanical properties at temperatures around 500°C, which is difficult for other materials to achieve. Therefore, in the automotive industry, titanium is regarded as an ideal material to replace steel to achieve lightweight and high performance.

Lightweight and energy-saving

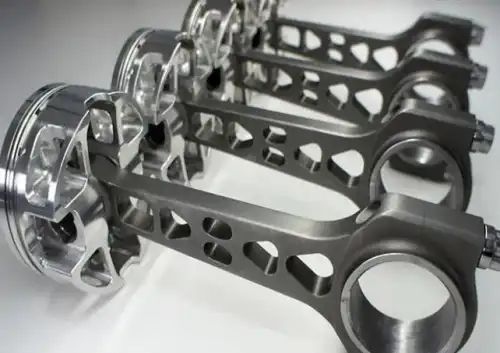

The lightweight characteristics of titanium are one of the main reasons it is so popular in the automotive industry. Automotive parts made of titanium, such as engine connecting rods, valves, valve spring seats, and springs, can significantly reduce the overall weight of the vehicle. This not only reduces the vehicle's fuel consumption and improves fuel efficiency, but also reduces exhaust emissions, helping to achieve the energy conservation and emission reduction goals of the automotive industry.

Corrosion resistance and durability

Titanium also has excellent corrosion resistance and can maintain stable performance in harsh working environments. This feature makes titanium an ideal material for manufacturing key automotive components, such as engine components and exhaust systems. These components can resist corrosion and wear during long-term use, extend service life, and reduce maintenance costs.

Innovative applications

In the automotive industry, the application of titanium has achieved remarkable results. For example, the Ferrari 315LV8 is one of the first cars to use titanium alloy connecting rods. This innovative design not only reduces the weight of the vehicle but also improves the performance of the engine. In addition, titanium alloys are also widely used in the manufacture of engine valves, valve spring seats, and springs, bringing higher performance and better driving experience to the car.

Looking to the future

With the continuous development of science and technology and the continuous advancement of titanium metal processing technology, the application prospects of titanium metal in the automotive industry will be broader. In the future, we are expected to see more automakers adopt titanium materials to promote the automotive industry to develop in a more efficient, environmentally friendly, and safe direction. At the same time, as the cost of titanium metal gradually decreases, its popularity will continue to increase, bringing high-quality automotive products and services to more consumers.