Titanium alloy, the jewel of the metal world, has taken its place in many high-tech fields due to its unique physical and chemical properties. Its density is about 60% of that of steel, which means that in the same volume, titanium alloy is much lighter than steel. This characteristic has made titanium alloys the material of choice in high-tech fields such as aerospace, because it not only reduces weight, but also reduces energy consumption and improves flight efficiency.

However, the advantages of titanium alloys do not end with their lightweight properties. High strength and heat resistance are also two highlights that cannot be ignored. Under extremely high temperatures and pressures, titanium alloy maintains excellent stability and durability, making it play an irreplaceable role in the aerospace and military industries.

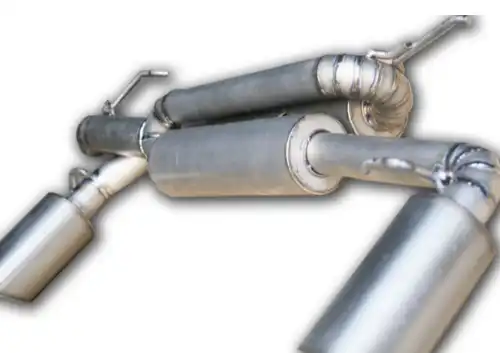

With the rapid development of the automotive industry, especially the growing prosperity of the sports car market, consumers are demanding more and more lightweight cars. Titanium alloy has naturally become the favorite of sports car manufacturers and tuning enthusiasts due to its advantages of lightweight, high strength, and heat resistance. However, the relatively high price of titanium alloy material prevents it from being popularized in general original cars. However, this has also provided the personalized tuning market with a wide scope for development.

In the market, the price difference between titanium alloys of different purities is obvious. The higher the purity of the titanium alloy, the degree of stretching (bending) and the degree of high-temperature resistance tend to be better. However, it is worth noting that purity is not the only factor that determines the performance of titanium alloys. In areas of greater curvature, titanium alloys still need to be formed by cutting and welding. titanium alloys are much more difficult to weld than steel, and only experienced welders can do the job. Therefore, in addition to the price of the material itself, the difficulty of processing is also one of the important reasons for the high price of titanium alloy exhaust pipes and other components.

Nevertheless, the use of titanium alloys in the field of automobile tuning is still in full swing. The specially processed titanium alloy tailpipes can be presented in a variety of colors, adding a touch of unique luxury to the sports car. At the same time, the lightweight nature of titanium alloy further enhances the performance and driving experience of sports cars. Whether it is accelerating, braking, or cornering, titanium alloy can bring better performance to the sports car.

In summary, titanium alloy, with its unique physical and chemical properties, plays an irreplaceable role in the field of high technology and the car modification market. With the progress of science and technology and the continuous development of the market, we believe that titanium alloy will show its unique charm and value in more fields.