Are titanium springs good?

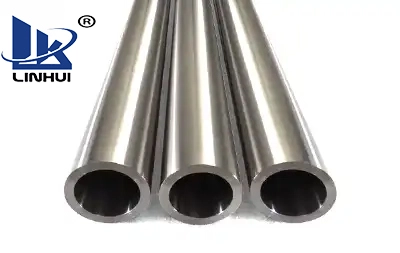

Titanium alloy springs have the advantages of small size, lightweight, excellent corrosion resistance, and fatigue resistance. Since the shear modulus of titanium alloy materials is larger than that of steel, the number of turns required to be bent is less than that of steel springs. Even if the specific gravity of the two materials is the same, titanium alloy springs are lighter than steel springs because they use less material. In most cases, the weight of titanium alloy springs is 60% to 70% lighter than steel springs, and the height design of titanium alloy springs can also be reduced, which is 50% to 80% lower than steel springs.

Another advantage of titanium springs is corrosion resistance. In standard salt spray corrosion fatigue tests, the fatigue life of general steel springs is reduced by 50% compared to that in air. In the same test, the fatigue life of the titanium spring was only 4% lower than that in the air. Moreover, unlike steel springs, titanium alloy springs do not require protective coatings.

Spring is a relatively special part. It is widely used in various fields of national production and life, such as cars, motorcycles, bicycles, and other means of transportation. Springs are used in daily necessities such as computers, clocks, light switches, toys, and clips. , mainly plays the role of shock absorption and energy storage.

Can titanium be used as a spring?

In recent years, titanium alloy has become a new choice for spring materials due to its high specific strength, low elastic modulus, and good corrosion resistance. Compared with steel springs, titanium springs have the advantages of lightweight, small size, and high resonance frequency. Their density and elastic modulus are only half of those of steel springs, but their strength is almost the same as that of steel springs. Due to these advantages, titanium springs can be designed to have smaller diameters, fewer turns, and significantly lower weight than steel springs in practical applications.

As far as titanium springs are concerned, high strength is the most important performance requirement for materials, so high-strength beta titanium alloys, such as Ti-3Al-8V-6Cr-4Mo-4Zr and Timetal LCB (Ti-6.8Mo-4.5Fe-1.5Al ) alloy is used to make springs.