Drink into the world of advanced accoutrements and slice-edge engineering with ASTM B863 Titanium Rod. This remarkable product has revolutionized colorful diligence with its exceptional parcels and protean operations. In this blog, we will claw into the composition, benefits, and operations, and epitomize why ASTM B863 Titanium Rod is a game-changer in the realm of accoutrements wisdom.

Composition:

ASTM B863 Titanium Rod is crafted from high-quality titanium amalgamation, meeting the strict norms set by the American Society for Testing and Accoutrements( ASTM). The amalgamation, primarily composed of titanium, is strengthened with precisely named rudiments, including aluminum and vanadium. This unique combination results in a material famed for its excellent strength-to-weight rate, erosion resistance, and outstanding continuity.

Benefits:

High Strength:The titanium amalgamation used in ASTM B863 Rod exhibits emotional strength, making it ideal for operations where continuity and cargo- bearing capacity are pivotal.

Corrosion Resistance:One of the name features of titanium is its exceptional resistance to erosion, indeed in harsh surroundings. This makes the ASTM B863 Titanium Rod a favored choice for operations in sharp settings, similar as marine and chemical diligence.

Low viscosity: Titanium is known for its low viscosity, making ASTM B863 Rod incredibly featherlight without compromising on strength. This specific is particularly profitable in aerospace and automotive operations, contributing to fuel effectiveness and bettered performance.

Biocompatibility: The biocompatibility of titanium makes it suitable for medical implants and bias. ASTM B863 Rod, with its impeccable quality, ensures the safety and comity needed for medical operations.

Operations:

The versatility of ASTM B863 Titanium Rod is reflected in its wide range of operations across colorful diligence

Aerospace Industry :Used in aircraft factors, where featherlight yet strong accoutrements are essential for energy effectiveness and performance.

Medical Field :Employed in the manufacturing of medical implants, similar as dental implants, bone screws, and prosthetic bias, owing to its biocompatibility.

Chemical Processing: Ideal for factors in chemical processing shops due to its erosion resistance, icing life in aggressive chemical surroundings.

Sports :Equipment set up in the product of high- performance sports outfit, similar as golf clubs and bike frames, where the combination of strength and low weight is pivotal.

Summary:

In conclusion, ASTM B863 Titanium Rod stands as a testament to the advancements in accoutrements wisdom, offering a combination of strength, erosion resistance, and low viscosity. Whether soaring through the skies in aerospace operations, abetting in medical advancements, or enhancing the performance of sports outfit, this titanium rod has come a foundation in colorful diligence. Embracing ASTM B863 Titanium Rod isn't just a choice; it's a commitment to excellence and invention in engineering.

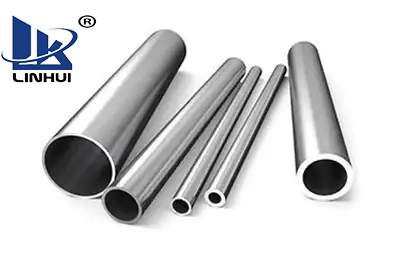

"Standard: ASTM B863

Grade: Grade 2, Grade 5, Grade 23

Type: Straight wire, Coiled wire

Titanium rod for Glasses: Dia. 1.6-8.0mm, Tolerance: ±0.04mm, Standard: ASTM B863"

Made in China, quality trust, choose Linhui, is to choose quality choose reputation, our factory production related to high quality products. E-mail: linhui@lksteelpipe.com

What's Titanium Grade 1 according to ASTM B265?

Titanium Grade 1, as defined by ASTM B265, is a commercially pure titanium grade known for its excellent erosion resistance, high rigidity, and formability. This unadulterated titanium possesses a low oxygen content, making it particularly resistant to erosion in colorful surroundings.

What are the crucial characteristics of Titanium Grade 1 per ASTM B265?

Pure Titanium ASTM B265 designates Grade 1 titanium as unadulterated titanium with a minimal chastity of99.5, icing a high- quality and homogeneous material.

Corrosion Resistance :Titanium Grade 1 exhibits superb resistance to erosion, making it suitable for operations in chemical processing, marine surroundings, and other sharp settings.

Formability :This grade is largely ductile and fluently formable, allowing for a variety of manufacturing processes similar as cold forming, hot forming, and welding.

What are the common operations of Titanium Grade 1 as per ASTM B265?

Chemical Industry Used in chemical processing outfit, including vessels and pipes, due to its erosion resistance in the presence of colorful chemicals.

Medical Implants :Titanium Grade 1 is employed in medical operations, similar as surgical implants and bias, owing to its biocompatibility and low threat of antipathetic responses.

Aerospace: Components employed in aerospace engineering for its combination of featherlight parcels and erosion resistance, contributing to the construction of aircraft factors.