Zirconium 702 is a high-performance alloy material, mainly composed of the element zirconium, zirconium 702 chemical composition contains a certain proportion of nickel, iron, silicon, manganese, and other elements. The following is a specific introduction to zirconium 702:

What is the chemical composition of zirconium?

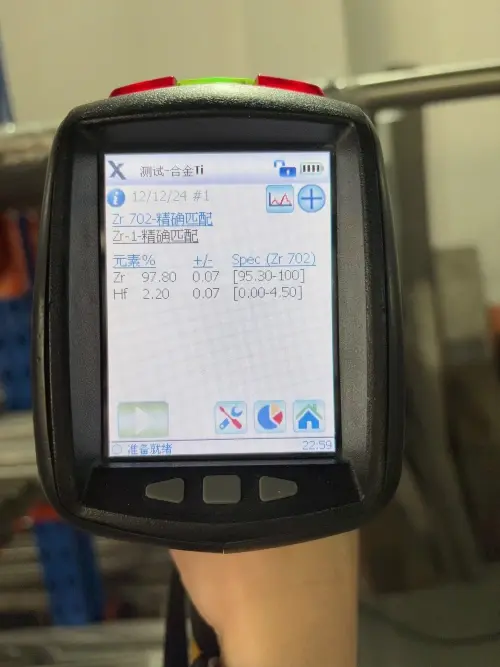

The zirconium 702 chemical composition includes the following elements:

Zirconium: Usually between 99.2% and 99.7%, it is the main component of the alloy and gives it excellent corrosion resistance and chemical stability.

Iron: Contained at 0.02% or less, the addition of iron improves the strength and hardness of the alloy.

Chromium: Contained at 0.05% or less, adding chromium alloy increases oxidation resistance, especially to oxidizing media.

Countersinking (HF): content is usually less than 4%, countersinking can be added to improve the corrosion resistance and heat resistance of the alloy.

Nickel: with a content of about 2%, it helps improve the alloy's mechanical properties and corrosion resistance of the alloy.

Silicon and manganese: these elements are present as impurities in amounts not exceeding 1%.

These elements' precise control and combination make zirconium 702 a high-performance alloy material. The zirconium 702 chemical composition enables it to be widely used in the chemical industry, nuclear industry, medical equipment, and aerospace industry.

Physical Properties

Density: about 6.5g/cm³.

Melting point: up to 1852℃, which makes zirconium 702 still maintain stable performance in high-temperature environments.

Thermal and electrical conductivity: good performance.

Coefficient of linear expansion: smaller than titanium, about 2/3 of titanium, small welding deformation, low stress, and favorable welding.

Characteristics

1. Corrosion resistance:

In a variety of acid solutions, it is in all boiling concentrations of hydrochloric acid, that the corrosion rate is less than 0.025mm/a.

In a sulfuric acid environment, the concentration does not exceed 70%, zirconium 702 chemical composition has excellent corrosion resistance.

Compared with other metal materials, its chemical corrosion resistance has significant advantages over cobalt alloys and many high-grade stainless steel, titanium, and aluminum alloys.

In terms of resistance to corrosion by oxidizing acids, such as sulfuric acid, hydrochloric acid, and other acids, zirconium 702 far outperforms titanium.

Zirconium 702 maintains good corrosion resistance in most inorganic acids, organic acids, alkali solutions, salt solutions, and some molten salts.

However, it is not corrosion resistant in a few media such as hydrofluoric acid, ferric chloride, copper chloride, aqua regia, concentrated sulfuric acid, and wet chlorine gas. High temperatures and pressure of water, steam, and liquid metals also have a certain degree of corrosion resistance.

2. Mechanical properties:

The tensile strength reaches 380MPa.

Yield strength of 205MPa. elongation of 16%.

It shows that zirconium 702 chemical composition has high strength and certain ductility.

3. High temperature resistance:

In a high-temperature environment can maintain stable performance.

The surface will spontaneously form a layer of good adhesion of protective oxide film, this layer of oxide film at high temperatures has a strong self-healing ability.

Even at a high temperature of 300℃, it can effectively protect the zirconium 702 substrate from corrosion and damage.

Applications

The chemical composition and physical properties of zirconium 702 show a wide range of applications in many fields:

Chemical industry: used in the manufacture of heat exchangers, valves, and other key components to ensure stable operation in corrosive media.

Aerospace field: suitable for the manufacture of certain parts of aircraft engines, to improve the safety and reliability of flight.

In the field of nuclear industry: it is used to manufacture reactor structural parts, fuel elements, and other key components, providing a guarantee for the safe and stable utilization of nuclear energy.

Automobile field: it can be used to manufacture automobile engine parts, transmission system parts, etc., to improve the fuel efficiency and power performance of automobiles.

Construction field: used in the manufacture of structural parts of high-rise buildings, bridges, and other key components to enhance the safety and stability of buildings.

In summary, zirconium 702 chemical composition and excellent physical properties of high-performance alloy materials, in some fields with a wide range of application prospects. Email:linhui@lhtitanium.com