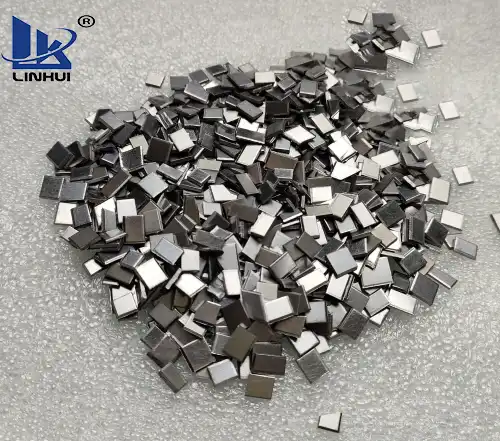

Tantalum Block

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

Tantalum Block: High-Performance Material for Critical Applications

Introduction

Tantalum is a rare, highly corrosion-resistant metal that excels in extreme environments, making it an ideal material for various high-performance applications. Whether you're involved in aerospace, medical equipment manufacturing, or chemical processing, Tantalum Block offers unmatched durability, stability, and strength. At LINKUN TITANIUM, we provide premium-quality tantalum blocks designed to meet the most stringent industry standards, ensuring that your operations remain reliable and efficient.

Specifications

| Specification | Description |

|---|---|

| Material Type | Tantalum |

| Purity | ≥99.95% |

| Dimensions | Custom sizes available upon request |

| Shape | Blocks, plates, or customized forms |

| Density | 16.6 g/cm³ |

| Melting Point | 3017°C |

| Hardness | 6.5-7.0 (Mohs scale) |

| Thermal Conductivity | 55 W/m·K |

| Electrical Resistivity | 0.138 µΩ·m |

| Application Temperature | Up to 3000°C |

Why Choose Us as Your Supplier?

Unmatched Product Quality

At LINKUN TITANIUM, we offer tantalum blocks that meet the highest industry standards. Our products undergo rigorous quality control processes to ensure consistent quality and exceptional performance. Whether you’re in the aerospace, defense, or petrochemical industries, Tantalum Block is engineered to withstand extreme temperatures and harsh environments.

Efficient Logistics & Packaging

Our global presence allows us to deliver Tantalum Block worldwide. We prioritize efficient logistics to ensure timely delivery of your orders. All our products are carefully packaged to avoid damage during transportation, giving you peace of mind and guaranteeing that your materials arrive in perfect condition.

Advanced Manufacturing Facility

Located in Xi’an, China, our modern facility is equipped with cutting-edge technology and equipment to produce high-quality tantalum products. We take pride in maintaining a clean and advanced production environment, ensuring every product meets our stringent quality assurance guidelines.

Customer-Centric Service

Our team is dedicated to providing exceptional customer service. From initial inquiries to post-purchase support, we ensure a seamless experience. We offer technical assistance, product customization, and after-sales support to meet your unique needs.

Trusted by Industry Leaders

We are proud to have established long-term relationships with renowned companies such as CEFC, PTT, PETROECUADOR, and LUKOIL. Our commitment to quality and service has made us a trusted supplier to industries worldwide.

Production Process

The production of Tantalum Block follows a strict, multi-step process to guarantee the highest quality:

- Sourcing: We use premium-grade tantalum raw materials from certified suppliers to ensure superior product quality.

- Melting: The raw materials are melted under controlled conditions, using advanced vacuum arc remelting (VAR) or electron beam melting (EBM) methods for precise composition.

- Forming: The molten tantalum is then formed into blocks using hot forging or casting, followed by annealing to relieve internal stresses.

- Machining: The blocks are precision-machined to the required dimensions and specifications, ensuring uniformity and high performance.

- Inspection: Each batch undergoes rigorous quality control checks, including X-ray, ultrasonic testing, and dimensional verification.

- Packaging: Finally, our tantalum blocks are carefully packaged and prepared for shipment to ensure that they reach our customers safely and on time.

Product Advantages and Characteristics

- Corrosion Resistance: Tantalum is one of the most corrosion-resistant metals, making it ideal for use in aggressive chemical environments, such as reactors and pipelines in the chemical, petrochemical, and energy industries.

- High Melting Point: Tantalum’s melting point of 3017°C makes it suitable for high-temperature applications in aerospace, defense, and power generation industries.

- Biocompatibility: Tantalum is non-toxic and highly biocompatible, making it an excellent choice for medical equipment and implants.

- High Strength and Durability: Despite its lightweight, tantalum has exceptional strength, ensuring longevity and minimal wear in critical components.

- Easy Machining: Tantalum is easier to machine than many other refractory metals, enabling precise manufacturing of complex parts.

Application Areas

Tantalum blocks are essential in industries that require materials capable of withstanding extreme conditions, including:

- Aerospace and Defense: Tantalum block is used in high-performance applications like jet engine components, missile guidance systems, and aerospace structures.

- Marine and Offshore: Due to its excellent resistance to saltwater corrosion, tantalum is ideal for use in ships, submarines, and offshore oil rigs.

- Chemical and Petrochemical: Tantalum is used in the construction of chemical reactors, heat exchangers, and pressure vessels for processing aggressive chemicals.

- Energy (Oil & Gas, Power Generation): Tantalum Block is vital for applications involving high-temperature environments, such as power plants and oil and gas exploration.

- Medical Equipment: Tantalum is used in surgical implants, diagnostic equipment, and medical devices due to its biocompatibility and strength.

- Automotive (High-Performance): Tantalum's high strength and resistance to heat make it an excellent choice for high-performance automotive components, especially in racing applications.

Our Factory

LINKUN TITANIUM operates a state-of-the-art manufacturing facility, equipped with the latest technology for producing premium titanium and Tantalum Block products. Our factory is designed for efficiency, precision, and safety, enabling us to produce products that meet the highest quality standards. With a team of experienced engineers and technicians, we are committed to delivering top-tier materials for critical applications worldwide.

Certification

We are proud to have achieved several industry certifications, including:

- ISO 9001:2015 QMS Certificate

- ISO 14001:2015 Environmental Management Certificate

- OHSAS 18001:2007 Health and Safety Management Certificate

- TUV Nord AD2000-W0 Certification

- PED 2014/68/EU Certification

- ABS, BV, CCS, DNV, and other certifications

Our certifications demonstrate our commitment to quality, environmental sustainability, and the highest safety standards, ensuring that our customers receive reliable and certified products.

Frequently Asked Questions

What are the typical applications of tantalum blocks?

Tantalum block is used in aerospace, defense, medical devices, chemical processing, energy, and high-performance automotive applications due to its corrosion resistance, high strength, and durability.

How do I place an order?

You can easily contact us via email at linhui@lhtitanium.com or through our website for product inquiries and to place orders.

Can I get customized tantalum blocks?

Yes, we offer customized tantalum blocks based on your specific requirements. Contact us with your specifications, and we’ll work with you to deliver the perfect solution.

What is the lead time for delivery?

Our standard lead time is typically 4-6 weeks, depending on the complexity of your order. However, we strive to accommodate urgent requests where possible.

Contact Us

If you have any questions or need assistance, don't hesitate to reach out to our team. We are here to provide you with the best possible service and products.

- Email: linhui@lhtitanium.com

By choosing LINKUN TITANIUM for your Tantalum Block needs, you're partnering with a trusted leader in the industry. Our commitment to quality, innovation, and customer satisfaction ensures you receive the best materials for your critical applications.