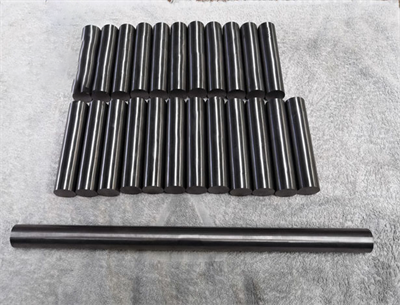

Tantalum rod

Tantalum rod, tantalum rod, tantalum wire Tantalum rod parameters and grades: R05200, R05400, Ta1, Ta10W, Ta2.5W Implementation standard: ASTM B365-98 GB/T14841-2008 Purity: ≥99.95% Density: ≥16.6g/cm3 Supply Status: Polished tantalum rod shape: straight rod, U-shaped rod, S-shaped rod (can be customized and produced according to customer requirements) Size range: Φ0.15xL (can be customized and produced according to customer requirements) Production process: raw material - Vacuum Electronics Beam melting-forging-polishing-finished tantalum rod. Usage of tantalum material: Mainly used in corrosion resistance and superconducting industries. It can be used as tantalum capacitors, tantalum electrodes, and tantalum processed parts. Construction period: Customized delivery within 10 days (spot goods can be shipped at any time)

Send InquiryProduct information:

Tantalum rod, tantalum rod, tantalum wire Tantalum rod parameters

Brand: R05200, R05400, Ta1, Ta10W, Ta2.5W

Implementation standard: ASTM B365-98 GB/T14841-2008

Purity: ≥99.95%

Density: ≥16.6g/cm3

Supply status: polished surface

Tantalum rod shape: straight rod, U-shaped rod, S-shaped rod (can be customized and produced according to customer requirements)

Size range: Φ0.15xL (can be customized and produced according to customer requirements)

Production process: raw materials - vacuum electron beam melting - forging - polishing - finished tantalum rods.

Usage of tantalum material: Mainly used in corrosion resistance and superconducting industries. It can be used as tantalum capacitors, tantalum electrodes, and tantalum processed parts.

Construction period: Customized delivery within 10 days (spot goods can be shipped at any time).

Payment terms: 30% deposit, 70% paid before delivery.

Packaging method: Packed in wooden boxes with plastic partitions, including material certificates, packing lists, and other accessories. The weight of a single box does not exceed 100kg.

Shipping method: express or logistics (negotiable)

Freight: The Supplier is responsible.

Post-service: If quality problems occur during the warranty period, the supplier shall bear all responsibilities (within the scope of normal use).

Tantalum material ingredient list

Tantalum rod, tantalum wire, tantalum-tungsten alloy rod (Ta-2.5W), tantalum-tungsten alloy wire (Ta-10W)

Brand: RO5200, RO5252(Ta-2.5W), RO5255(Ta-10W)

Specifications: ¢0.3~¢100mm

Implementation standard: ASTM B365-98

Ingredient description:

| Ingredients % | |||||||||||||

| brand | main ingredient | Impurity content Not more than | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | surplus | —— | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.01 |

| Ta2 | surplus | —— | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.002 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.01 |

| TaNb3 | surplus | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.02 | 0.01 | 0.0015 | 0.01 |

| TaNb20 | surplus | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.02 | 0.01 | 0.0015 | 0.01 |

| Ta2.5W | surplus | 0.005 | 0.005 | 0.002 | 3.0 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 | |

| Ta10W | surplus | 0.005 | 0.005 | 0.002 | 11 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 | |

| If the user has special requirements, the two sides specifically agree. | |||||||||||||

Tolerance range:

| Diameter, inches (mm) | Tolerance, +/- inches (mm) |

| 0.010~0.020 excl (0.254~0.508) | < 0.0005 (0.013) |

| 0.020~0.030 excl (0.508~0.762) | < 0.00075 (0.019) |

| 0.030~0.060 excl (0.762~1.524) | < 0.001 (0.025) |

| 0.060~0.090 excl (1.524~2.286) | < 0.0015 ( 0.038) |

| 0.090~0.125 excl (2.286~3.175) | < 0.002 (0.051) |

| 0.090~0.125 excl (2.286~3.175) | < 0.003 (0.076) |

| 0.187~0.375 excl (4.750~9.525) | < 0.004 (0.102) |

| 0.375~0.500 excl (9.525~12.70) | < 0.005 (0.127) |

| 0.500~0.625 excl (12.70~15.88) | < 0.007 (0.178) |

| 0.625~0.750 excl (15.88~19.05) | < 0.008 (0.203) |

| 0.750~1.000 excl (19.05~25.40) | < 0.010 (0.254) |

| 1.000~1.500 excl (25.40~38.10) | < 0.015 (0.381) |

| 1.500~2.000 excl (38.10~50.80) | < 0.020 (0.508) |

| 2.000~2.500 excl (50.80~63.50) | < 0.030 (0.762) |

Mechanical properties (annealed state):

| Rod, diameter 0.125 inch (3.18 mm) ~ 2.5″ (63.5 mm) | |||

| brand | Ultimate Tensile Strength Min, lbs/in2 (MPa) | Minimum Yield Strength, lbs/in2 (MPa) | Elongation, % min (1 inch gauge) |

| RO5200/RO5400 | 25000 (172) | 15000 (103) | 25 |

| RO5252 | 40000 (276) | 28000 (193) | 20 |

| RO5255 | 70000 (482) | 55000 (379) | 20 |

| RO5240 | 35000 (244) | 15000 (103) | 25 |

| Wire, diameter, inches (mm) | |||

| brand | Diameter, inches (mm) | Ultimate Tensile Strength Min, lbs/in2 (MPa | Elongation, min % |

| RO5200/RO5400 | 0.010(0.254)~0.0149(0.379) | 35000 (241) | 10 |

| 0.015(0.381)~0.0249(0.633) | 35000 (241) | 15 | |

| 0.025(0.635)~0.124(3.14) | 30000 (207) | 20 | |

| RO5252 | 0.010(0.254)~0.0149(0.379) | 40000 (276) | 5 |

| 0.015(0.381)~0.0249(0.633) | 40000 (276) | 10 | |

| 0.025(0.635)~0.124(3.14) | 40000 (276) | 15 | |

| RO5255 | 0.010(0.254)~0.0149(0.379) | 70000 (482) | 5 |

| 0.015(0.381)~0.0249(0.633) | 70000 (482) | 10 | |

| 0.025(0.635)~0.124(3.14) | 70000 (482) | 15 | |

| RO5240 | 0.010(0.254)~0.0149(0.379) | 35000 (244) | 10 |

| 0.015(0.381)~0.0249(0.633) | 35000 (244) | 15 | |

| 0.025(0.635)~0.124(3.14) | 35000 (244) | 20 | |

The 10-inch (254 mm) pitch applies to 0.050 inches (1.27 mm) diameter; the 1-inch (25.4 mm) or 2-inch (50.8 mm) pitch applies to greater than 0.050 inches (1.27 mm) diameter.

If there are any Tantalum rod requirements, both parties shall specifically agree.