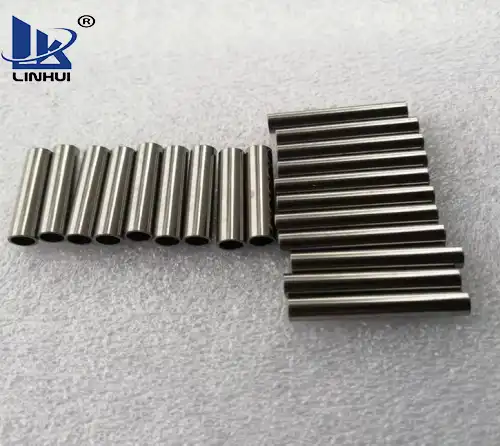

Tantalum Seamless Tube

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

Tantalum Seamless Tube – Superior Quality and Durability for Demanding Applications

Introduction

Tantalum seamless tubes are a vital component in industries requiring high-performance materials that can withstand extreme conditions. Known for their corrosion resistance, excellent thermal properties, and strength at elevated temperatures, tantalum seamless tubes are indispensable in applications ranging from aerospace and defense to chemical processing. At Linhui Titanium, we pride ourselves on delivering the highest quality tantalum seamless tubes tailored to meet the rigorous standards of various industries. Whether you need them for aerospace, medical equipment, or petrochemical applications, our tubes are engineered for durability, reliability, and performance.

Specifications

| Property | Specification |

|---|---|

| Material Type | Tantalum (Ta) |

| Tube Type | Seamless |

| Outer Diameter (OD) | 6 mm – 100 mm |

| Wall Thickness (WT) | 0.5 mm – 10 mm |

| Length | Customizable (Up to 6 meters) |

| Grade | Ta1, Ta2, Ta10, Ta20 |

| Standard | ASTM B521, ASME SB521, ISO 9001:2015 |

| Surface Finish | Polished, Annealed, and Bright Finished |

| Temperature Resistance | Up to 300°C |

| Corrosion Resistance | Excellent (Resistant to hydrochloric acid, sulfuric acid, etc.) |

Why Choose Us as Your Tantalum Seamless Tube Supplier?

At Linhui Titanium, we are more than just a supplier; we are a reliable partner in your business success. Our tantalum seamless tubes are designed to meet the highest standards in the industry, offering exceptional durability and performance.

- Quality Assurance: We uphold stringent quality control measures throughout our manufacturing process, ensuring that every tube meets your exact specifications.

- Advanced Logistics and Packaging: Our efficient logistics system ensures timely delivery, while our packaging protects your products during transit, ensuring they reach you in pristine condition.

- Expert Team: Our team is committed to providing technical support, answering all queries, and ensuring a smooth ordering process.

- Customization: We offer tailored solutions to meet the unique needs of each project, including specific sizes, grades, and finishes.

Production Process

Our tantalum seamless tubes are produced using state-of-the-art machinery and techniques, ensuring precision and consistency. Here's an overview of our production process:

- Raw Material Selection: Only the finest quality tantalum is used, sourced from reputable suppliers.

- Forming and Drawing: The raw material is carefully drawn to the desired dimensions, ensuring uniformity and accuracy.

- Heat Treatment: Our tubes undergo precise heat treatment to enhance their strength and corrosion resistance.

- Finishing: After cooling, the tubes are polished or annealed to meet customer specifications and achieve the desired surface finish.

- Inspection and Testing: Each tube undergoes rigorous testing, including pressure testing, dimensional checks, and visual inspections to guarantee compliance with industry standards.

Product Advantages and Characteristics

- Corrosion Resistance: Tantalum’s exceptional resistance to corrosion makes it ideal for use in harsh environments, such as chemical processing, marine, and aerospace applications.

- High Strength-to-Weight Ratio: Despite its remarkable strength, tantalum is lightweight, making it ideal for industries where weight plays a critical role, such as aerospace and automotive.

- Thermal Stability: With excellent thermal properties, tantalum can perform effectively in high-temperature environments.

- Biocompatibility: Tantalum is highly biocompatible, making it suitable for use in medical equipment, such as surgical tools and implants.

Application Areas

Our tantalum seamless tubes are widely used in the following industries:

- Aerospace and Defense: Tantalum tubes are essential in the aerospace industry for fuel systems, missile components, and heat exchangers due to their ability to withstand high pressure and temperature.

- Marine and Offshore: Used in shipbuilding and offshore structures where resistance to saltwater corrosion is crucial.

- Chemical and Petrochemical: Ideal for environments involving highly corrosive chemicals and high temperatures.

- Energy (Oil & Gas, Power Generation): Essential in pipelines, reactors, and other high-performance equipment requiring durability under stress.

- Medical Equipment: Used in biocompatible medical devices, including surgical instruments and diagnostic equipment.

- Automotive (High-Performance Applications): Perfect for lightweight, high-strength automotive components, including those in racing vehicles.

Our Factory

Linhui Titanium operates a modern, state-of-the-art factory located in Xi'an, China. As a leading manufacturer of tantalum seamless tubes products, our factory is equipped with the latest technologies to ensure the highest production standards. We invest in continuous research and development, keeping our processes innovative and ensuring that we meet the evolving needs of our global customer base.

Certifications

We are committed to maintaining the highest standards of quality and safety, which is reflected in our certifications:

- ISO 9001:2015 (Quality Management System)

- OHSAS 18001:2007 (Occupational Health and Safety)

- ISO 14001:2015 (Environmental Management)

- PED 2014/68/EU (Pressure Equipment Directive)

- TUV Nord AD2000-W0 (Pressure Vessel Certification)

- DNV, BV, SGS, Moody's, ABS, LR, GL (Third-Party Inspection Agencies)

- China Special Equipment Manufacturing License

These certifications highlight our commitment to delivering tantalum seamless tubes products that meet international standards for quality and safety.

Frequently Asked Questions

-

What industries use tantalum seamless tubes?

- Tantalum tubes are commonly used in aerospace, chemical processing, marine, medical equipment, energy, and high-performance automotive sectors.

-

Can you customize the size of the tantalum seamless tube?

- Yes, we offer customization in terms of size, thickness, and length to meet your specific requirements.

-

What is the lead time for ordering tantalum seamless tubes?

- Lead times vary based on the order size and customization. Typically, we can deliver within 3-4 weeks.

-

Do you provide technical support?

- Yes, our expert team is available to assist with technical inquiries and provide guidance on selecting the right product for your needs.

Contact Us

For more tantalum seamless tubes information or to place an order, feel free to contact us at linhui@lhtitanium.com. Our team is ready to assist you with all your requirements.

_1739326366313.webp)