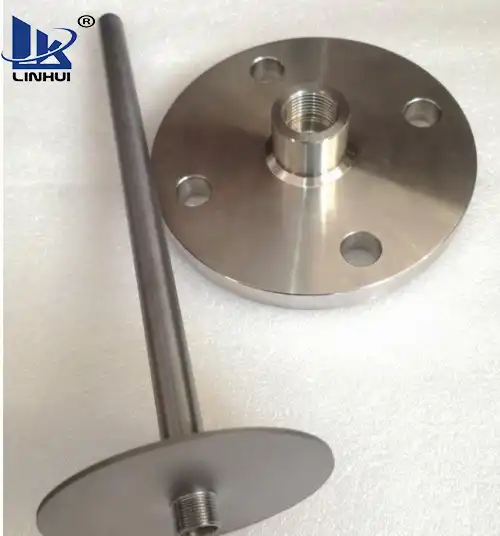

Tantalum Sleeves

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

Tantalum Sleeves: The Ideal Solution for High-Performance Applications

Introduction

Tantalum sleeves are a crucial component for various industries, offering unique benefits due to their excellent corrosion resistance, durability, and high melting point. Whether you're working in aerospace, defense, marine, chemical, petrochemical, or energy sectors, tantalum sleeves are indispensable in ensuring longevity and reliability in critical applications. As a leading supplier of titanium and tantalum products, we offer high-quality tantalum sleeves designed to meet the demands of the most challenging environments.

At LINKUN TITANIUM, we specialize in providing superior tantalum products that adhere to stringent industry standards. They are engineered to perform reliably under high stress and harsh conditions, making them the go-to choice for a wide range of industries worldwide.

Specifications

| Property | Value |

|---|---|

| Material | Tantalum |

| Grade | ASTM B365, ASTM B708 |

| Purity | 99.9% minimum |

| Melting Point | 3,017°C |

| Density | 16.6 g/cm³ |

| Corrosion Resistance | Excellent (acidic and alkaline environments) |

| Hardness | 250 Vickers |

| Max Operating Temperature | 3,000°C |

| Dimensions | Custom sizes available |

Why Choose Us as the Supplier of Tantalum Sleeves?

- High-Quality Products: Our tantalum sleeves are made with superior-grade materials, ensuring exceptional performance and reliability.

- Global Reach: With over two decades of experience in supplying titanium and tantalum products globally, we are trusted by top-tier companies in aerospace, defense, energy, and more.

- Logistics and Packaging: We ensure safe and secure packaging and on-time delivery to meet the needs of our international customers.

- Expert Team: Our team of engineers and quality control specialists ensures every product meets strict industry standards, providing you with peace of mind in your purchase.

- Customer-Centric Service: We offer personalized service, working with you to meet specific technical requirements and provide timely support.

Production Process

At LINKUN TITANIUM, we follow a rigorous production process to manufacture it that exceed industry standards. This includes:

- Material Sourcing: We use high-purity tantalum sourced from reputable suppliers.

- Fabrication: Advanced machinery is used for the precise fabrication of tantalum sleeves to meet custom specifications.

- Testing and Quality Control: Each sleeve undergoes strict testing for corrosion resistance, durability, and dimensional accuracy.

- Packaging and Delivery: The sleeves are carefully packaged and dispatched to ensure they reach you in perfect condition.

Product Advantages and Characteristics

- Corrosion Resistance: Tantalum is highly resistant to a wide range of acids, including sulfuric, hydrochloric, and nitric acid, making it ideal for use in chemical processing.

- High Melting Point: Tantalum can withstand extremely high temperatures, making it suitable for applications where heat resistance is a priority.

- Durability and Strength: They are incredibly durable, offering long-lasting performance under mechanical stress.

- Biocompatibility: Tantalum is highly biocompatible, making it an ideal material for medical devices and implants.

Application Areas

They are widely used in the following industries:

- Aerospace and Defense: Used in critical applications like turbine engines, military equipment, and spacecraft components.

- Marine and Offshore: Essential for components exposed to seawater, such as submersible equipment and offshore oil rigs.

- Chemical and Petrochemical: Used in reactors, pipelines, and heat exchangers where high resistance to corrosive substances is required.

- Energy (Oil & Gas, Power Generation): Ideal for equipment exposed to harsh environments like reactors and turbines.

- Medical Equipment: Tantalum’s biocompatibility makes it perfect for use in surgical instruments and implants.

- Automotive (High-Performance Applications): For lightweight, high-strength components in performance vehicles.

Our Factory

Linhui’s state-of-the-art facility is a leader in the titanium and tantalum product manufacturing industry. Our factory is equipped with advanced machinery and technology, ensuring precise manufacturing and consistent product quality. We are committed to providing high-performance products tailored to meet the unique needs of our customers.

Certifications

Linhui has obtained multiple industry certifications that attest to the quality and reliability of our tantalum sleeves:

- Manufacturing License of Special Equipment of China

- TUV Nord AD2000-W0 certification

- PED 2014/68/EU certification

- ISO 9001:2015 QMS Certificate

- ISO 14001:2015 Certificate

- OHSAS 18001:2007 Certificate

- CE, ABS, DNV, BV, and other industry-specific certifications

Frequently Asked Questions

-

What industries can use tantalum sleeves? Tantalum sleeves are used in aerospace, defense, marine, chemical, petrochemical, energy, medical, and automotive industries due to their durability and corrosion resistance.

-

What sizes do you offer? We offer custom sizes for tantalum sleeves, tailored to your specific needs and application requirements.

-

How do I place an order? Contact us via email or our website, and our team will assist you with your order.

-

What is the lead time for delivery? Delivery times depend on order size and location, but we aim to ship all orders promptly.

Contact Us

For more information or to request a quote, feel free to contact us at linhui@lhtitanium.com. Our expert team is here to help you with any questions and to provide the highest quality tantalum sleeves for your needs.