Nitinol Shape Memory Alloy Wire

Grade: Titanium nickel alloy

Standard: ASTM F2603-18/12

Strength: 790

Specifications: complete

Appearance: bright

Premium Nitinol Shape Memory Alloy Wire | Medical-Grade & Industrial Supplier

Nitinol Shape Memory Alloy Wire Supplier | Superelastic & Temperature-Responsive

Meta Description

High-performance Nitinol Shape Memory Alloy Wire for medical, aerospace & robotics. Custom diameters, ASTM F2063 compliant, with certified mechanical properties. Get a quote today!

Key Selling Points

✅ Medical & Industrial Grades – ASTM F2063 compliant

✅ Custom Diameters – 0.05mm to 5.0mm (±0.005mm tolerance)

✅ Precision Transformation Temperatures – Af from -20°C to +110°C

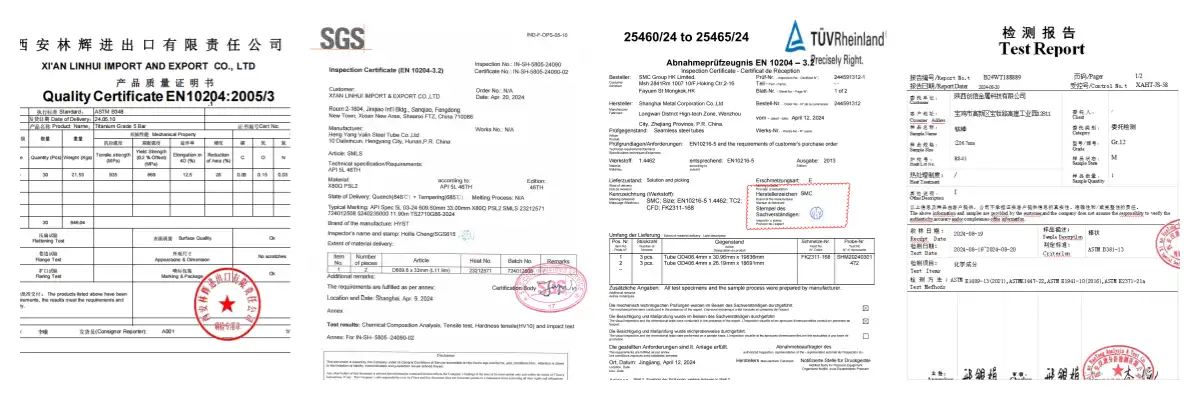

✅ Certified Material Traceability – Full Mill Test Reports

✅ Global Express Shipping – DDP/FOB/EXW options

Technical Specifications

1. Nitinol Wire Composition & Properties

Our Nitinol Shape Memory Alloy Wire meets strict ASTM F2063 standards:

Chemical Composition (%)

| Grade | Ti(%) | Fe(%) | C(%) | O (%) | N(%) | H(%) | Co(%) | Ni(%) |

| Nitinol | Remainder | 0.008 | 0.044 | 0.026 | 0.00 2 | 0.001 | / | 55.76 |

Mechanical Properties

| Property | Superelastic Grade | Memory Grade |

|---|---|---|

| Tensile Strength | ≥800 MPa | ≥1000 MPa |

| Elongation | ≥15% | ≥10% |

| Transformation Temp (Af)* | -20°C to +30°C | +70°C to +110°C |

| Cycle Life (Fatigue) | >100,000 cycles | >50,000 cycles |

*Custom Af temperatures available

2. Available Dimensions & Tolerances

| Diameter (mm) | Tolerance | Available Forms |

|---|---|---|

| 0.05 - 0.5 | ±0.002mm | Straightened/Spooled |

| 0.5 - 2.0 | ±0.005mm | Spooled (1-25kg coils) |

| 2.0 - 5.0 | ±0.01mm | Straight Cut Lengths |

Surface Finishes:

-

Etched (for medical devices)

-

Polished (Ra <0.2μm)

-

Oxide-Free (vacuum annealed)

3. Top Applications of Nitinol Shape Memory Alloy Wire

Medical Devices

-

Orthodontic archwires

-

Guidewires & stents

-

Surgical robotics components

Industrial Uses

-

Aerospace actuators

-

Automotive thermal valves

-

Robotics micro-actuators

Consumer Products

-

Eyeglass frames

-

Smart textiles

-

IoT temperature sensors

Competitive Advantages (Conversion-Focused)

🔹 30+ Years in Shape Memory Alloys

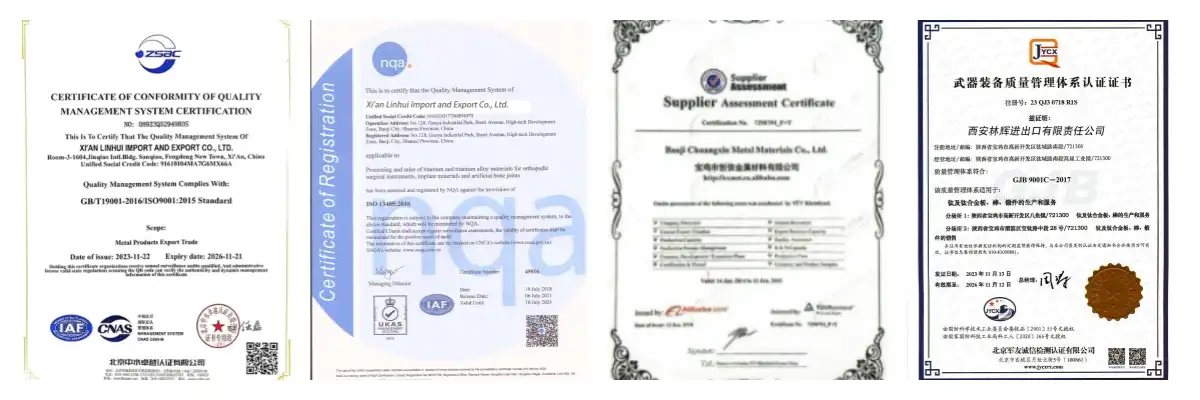

🔹 ISO 13485 Certified for medical applications

🔹 R&D Support – Custom Af/As temperatures

🔹 Lot Traceability – Full material certifications

🔹 Just-in-Time Inventory – 2-4 week lead time

FAQ

Q: How accurate are transformation temperatures?

✔ ±3°C tolerance for Af/As temperatures in medical-grade wire.

Q: Do you supply radiopaque Nitinol wire?

✔ Yes, Pt/Ir markers available for medical imaging.

Q: What’s the minimum order quantity?

✔ Prototype orders from 1kg accepted.

Q: Can you provide fatigue test data?

✔ Full ASTM F2516 test reports available.

Call-to-Action

📞 Call Now: +86-29-89506568

✉ Email: linhui@lhtitanium.com

📅Get Sample: [Free Test Samples for OEMs]

Limited Offer:

-

5% discount on first Nitinol Shape Memory Alloy Wire order >100kg

-

Free technical consultation