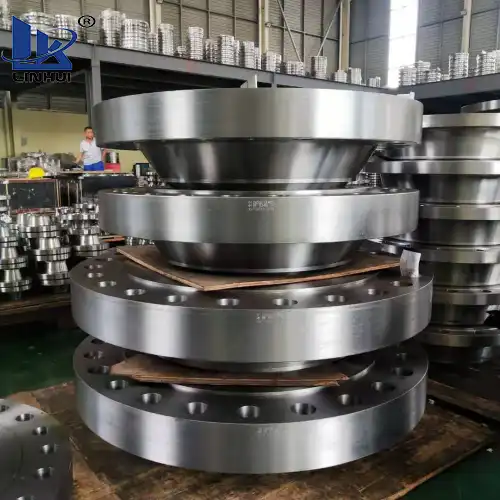

High-Strength Forged Flange

Standard: ASME, ANSI, API, DIN, BS, EN, JIS, JPI

Types: weld neck, slip-on, threaded, lap-joint, socket welding and blind

Size: DN10-DN600

Class: PN0.6Mpa, PN1.0Mpa, PN2.5Mpa, PN4.0Mpa, etc

ISO 9001 certificate, 3.1B, JIS, ABS, BV, DNV certificates provided

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

High-Strength Forged Flange Product Page

1. Introduction

Welcome to Xi'an Linhui Import and Export Co., Ltd., where we proudly offer high-strength forged flanges designed for demanding applications across various industries. Our titanium flanges are precision-engineered to provide exceptional strength, corrosion resistance, and longevity, making them ideal for sectors ranging from aerospace and defense to chemical processing and energy. Learn how our high-quality, durable products can elevate your projects and reduce maintenance costs.

2. Specifications

Below is a detailed overview of our high-strength forged flange specifications:

| Specification | Details |

|---|---|

| Material | Titanium and Titanium Alloys |

| Standard | ASME, ANSI, API, DIN, BS, EN, JIS, JPI |

| Types | Weld neck, Slip-on, Threaded, Lap-joint, Socket welding, Blind |

| Size | DN10-DN600 |

| Class | PN0.6Mpa, PN1.0Mpa, PN2.5Mpa, PN4.0Mpa, etc |

| Certificates | ISO 9001, 3.1B, JIS, ABS, BV, DNV |

| Production Capacity | Two factories with 30 titanium metal production lines, 800 tons annual production |

| Delivery Options | DHL, FEDEX, Air freight, Sea freight |

| Quality Control | ISO / SGS / TUV systems in place |

3. Why Choose Us as Your Supplier?

Our Advantages:

- High-Quality Materials: We use only the best titanium and titanium alloys for superior durability and performance.

- Advanced Manufacturing Facilities: Our two modern factories and 30 production lines enable us to meet large-scale demands quickly and efficiently.

- Strict Quality Control: We adhere to international quality standards (ISO, SGS, TUV) for every product we produce.

- Comprehensive Service: We offer customized solutions, fast lead times, and dedicated support throughout the purchasing process.

Logistics & Packaging:

- Secure, customized packaging solutions to ensure safe delivery.

- Flexible delivery terms via DHL, FedEx, air freight, and sea freight.

Our Team & Customer Service:

- Friendly and knowledgeable staff ready to assist with all technical and sales inquiries.

- Tailored support to meet your specific project needs.

4. Production Process

Our high-strength forged flanges undergo a meticulous production process to ensure maximum quality:

- Material Selection: Only high-grade titanium alloys are selected for production.

- Forging: Precision forging techniques are used to enhance strength and durability.

- Machining: Advanced CNC machining ensures exact specifications and smooth finishes.

- Heat Treatment: Optimizes mechanical properties for demanding environments.

- Quality Inspection: Every flange is rigorously tested to ensure compliance with international standards.

5. Product Advantages and Characteristics

- Superior Strength: High load-bearing capacity suitable for extreme conditions.

- Corrosion Resistance: Ideal for marine, chemical, and petrochemical applications.

- Lightweight Design: Offers a high strength-to-weight ratio, reducing overall system weight.

- Cost Efficiency: Durable with minimal maintenance, providing long-term savings.

- Versatile Compatibility: Compatible with various connection types, sizes, and pressure classes.

6. Application Areas

- Aerospace & Defense: Essential for lightweight, high-strength components in aircraft and military equipment.

- Marine & Offshore: Protects against saltwater corrosion, extending service life in challenging environments.

- Chemical & Petrochemical: Ensures safety and reliability in harsh chemical processing environments.

- Energy Sector: Ideal for pipelines, reactors, and high-stress systems.

- Medical Equipment: Suitable for biocompatible and sterile applications.

- Automotive (High-Performance): Lightweight and strong, perfect for racing and performance cars.

7. Our Factory

Linhui is a modern, state-of-the-art facility that occupies a leading position in the titanium industry. We are dedicated to providing high-quality, high-performance High-Strength Forged Flange products to customers around the globe.

8. Certifications

We hold the following certifications:

- Manufacturing License of Special Equipment of China

- TUV Nord AD2000-W0

- PED 2014/68/EU Certification

- ISO 9001:2015 QMS, OHSAS 18001:2007, ISO 14001:2015 Certificates

- Third-party approvals from DNV, BV, SGS, Moody's, TUV, ABS, LR, GL, PED, RINA, KR, NKK, AIB-VINEOTTE, CEIL, VELOSO, CCSI, and more.

9. Frequently Asked Questions

Q1: What is the lead time for high-strength forged flanges?

A1: Lead times vary based on order size and specifications but generally range from 2-4 weeks. Expedited options are available.

Q2: Are your flanges compliant with international standards?

A2: Yes, our products comply with ASME, ANSI, API, DIN, BS, EN, JIS, and more.

Q3: Can I request custom specifications?

A3: Absolutely! Contact us to discuss your custom project needs.

10. Contact Us

For more information or to place an order, please contact us at linhui@lhtitanium.com. Our dedicated team is ready to help with all your high-strength forged flange needs.