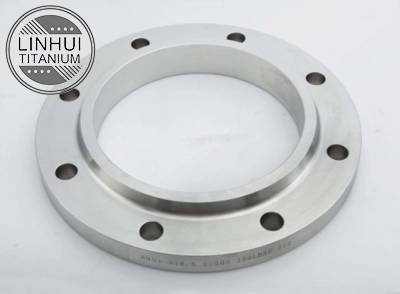

Socket Weld Flange

Factory direct supply, more reliable quality

1. Good craftsmanship, forging process

CNC precision turning, and CNC eyeleting, with specialized material testing equipment for flaw detection.

2. Strong performance, high compressive strength Strong compression resistance, easy-to-use links, able to withstand greater pressure

3. Good wear resistance, smooth surface

Smooth surface without burrs, strong tensile strength, corrosion-resistant, long-lasting use without rust, not easy to deform in a humid environment for long-term use

4. Good raw materials, materials selected with care

Selection of excellent Socket Weld Flange materials, body molding convenient fastening, easy to operate, have a strong fastening performance

Socket Weld Flange

Flanges for petroleum, chemical, and other industries

Socket weld flanges are flanges where the end of the pipe is inserted into the flange ring step and welded at the end and outside of the pipe. There are two kinds of flanges with and without neck. Necked pipe flanges have good rigidity, small welding deformation, and better sealing, and can be used when the pressure is 1.0~10.0MPa. B-type flanges for containers are also socket weld flanges, which are used in occasions with high sealing requirements. When designing, socket weld flanges can be calibrated as integral flanges.

Sealing surface form

Raised face (RF), concave-convex face (MFM), tongue and groove face (TG), ring joint face (RJ).

Material

Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1,LF2

CL1/CL2,LF3 CL1/CL2,ASTM A694 F42,F46,F48,F50,F52,F56,F60,F65,F70;

Stainless Steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti,

0Cr18Ni9Ti, 321, 18-8;

Alloy Steel (Alloy Steel): ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12,

A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/III;

Manufacturing standards

ANSI B16.5, HG20619-1997, GB/T9117.1-2000-GB/T9117.4-200, HG20597-1997

Connection method

Flange nut, bolt connection

Production process

Specialized whole Socket Weld Flange forging, forging and pressing manufacture, etc.

Processing method

High-precision CNC lathe turning, ordinary lathe fine turning, argon arc welding, and other processing.

Application

Boiler pressure vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food, and other industries socket welding flange: commonly used in PN ≤ 10.0MPa, DN ≤ 40 pipelines;

Precision forging Fine craftsmanship

Factory direct supply, more reliable quality

1. Good craftsmanship, forging process

CNC precision turning, and CNC eyeleting, with specialized material testing equipment for flaw detection.

2. Strong performance, high compressive strengthStrong compression resistance, easy-to-use links, able to withstand greater pressure

3. Good wear resistance, smooth surface

Smooth surface without burrs, strong tensile strength, corrosion-resistant, long-lasting use without rust, not easy to deform in a humid environment for long-term use

4. Good raw materials, materials selected with care

Selection of excellent Socket Weld Flange materials, body molding convenient fastening, easy to operate, have a strong fastening performance