Titanium Disc

Standard: ASTM B348, ASTM B381

Standard: ASTM F67, ASTM F136

Processing: forging, CNC

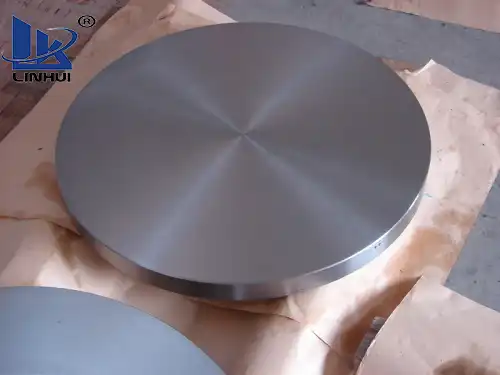

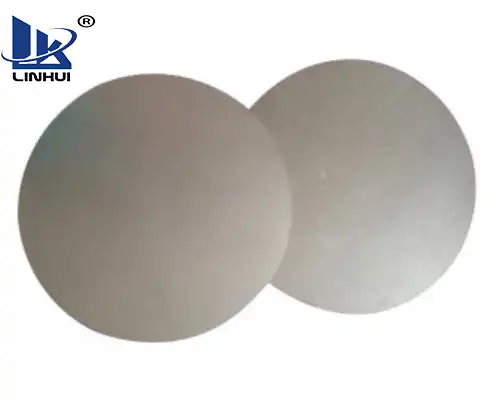

Titanium Disc is a round, flat metal product made of titanium metal. Titanium Disc usually has a smooth surface and a silver-gray metallic luster. The diameter and thickness of it can be customized according to different production needs and application scenarios.

| Product name | Titanium disc (titanium alloy disc) |

| Standard | ASTM-B381 ASTM-F136 ASTM-F67 AMS -4928 |

| Grade | Gr1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 7, Gr 9, Gr 11, Gr 12 |

| Condition | R/ M |

| Specification |

Diameter 50-2000mm Customized specification and shape accepted. |

| Surface | Bright Polishing and machined surface |

| Processing | Hot forging, Linear cutting, Water jet cutting |

Performance characteristics of Titanium Disc

1. High strength and light weight

Titanium has high strength, but its density is relatively low, about 60% of steel. This makes Titanium Disc lighter while ensuring strength, and is very suitable for applications in fields with strict weight requirements, such as aerospace, automobile manufacturing, etc.

2. Excellent corrosion resistance

Titanium exhibits excellent corrosion resistance in most environments and can resist corrosion from a variety of corrosive media such as acids, alkalis, and salts. This makes titanium Disc have a wide range of application prospects in corrosive environments such as chemical industry and marine engineering.

3. Good high temperature performance

Titanium can still maintain good strength and stability at high temperatures, and its high temperature resistance is better than many other metal materials. Therefore, it can also play an important role in high temperature working environments such as aircraft engines and high temperature industrial furnaces.

Application

Aerospace field

In the aerospace field, They are widely used to manufacture aircraft engine parts, structural parts, etc. Due to the high strength, light weight and high temperature resistance of them, they can meet the strict requirements of aerospace aircraft for the performance of parts, help reduce the weight of aircraft, and improve fuel efficiency and flight performance.

Chemical field

Chemical equipment usually needs to operate in a corrosive environment. Titanium Disc are often used to manufacture parts of chemical pipelines, valves, reactors and other equipment due to their excellent corrosion resistance. It can effectively resist the erosion of chemical substances, extend the service life of equipment, and ensure the safe and stable progress of chemical production.

Medical device field

Titanium has good biocompatibility and has been widely used in the field of medical devices. They can be processed into medical device parts such as artificial joints, bone plates, screws, etc., have good compatibility with human tissues, will not cause rejection reactions, and help patients' rehabilitation and treatment.

Automobile manufacturing field

With the development of automobile lightweight technology, they have also begun to be used in automobile manufacturing. For example, the engine parts and suspension systems of some high-performance cars are made of them, which can not only reduce the weight of the car, but also improve the performance and reliability of the car.

In short, Titanium Disc have become an indispensable and important material in modern industry with their unique performance characteristics and wide application fields. In the future, with the continuous advancement of technology and changes in market demand, the development prospects of titanium wafers will be even more exciting.