Description

Titanium Grade 7 Alloy (Ti-0.15Pd) is identical (0.12%-0.25% Pd) except for impurity limits. The additive Palladium (Pd) is for corrosion resistance which is very effective for improving crevice corrosion at elevated temperatures and when in contact with mildly reducing or variable oxidizing-reducing media. Properties are very similar to Ti Grade 2 because the addition of a small amount of Pd does not significantly change the microstructure. Titanium Grades 1, 2, 3, 4, 7, 11, and 12 are all considered unalloyed and have similar mechanical properties.

Ti-0.15Pd Alloy Plate Chemical Composition:

| Elements | Metric |

| Carbon, C | <= 0.10 % |

| Hydrogen, H | <= 0.015 % |

| Iron, Fe | <= 0.30 % |

| Nitrogen, N | <= 0.030 % |

| Other, each | <= 0.050 % |

| Other, total | <= 0.30 % |

| Oxygen, O | <= 0.25 % |

| Palladium, Pd | 0.12 – 0.25 % |

| Titanium, Ti | 99 – 99.8 % Remainder |

Physical Property:

| Physical Properties | Metric |

| Density | 4.50 g/cc |

Titanium Alloy Grade 7 Plate Mechanical Properties:

| Mechanical Properties | Metric |

| Hardness, Brinell | 200 |

| Hardness, Knoop | 222 |

| Hardness, Rockwell B | 75 |

| Hardness, Rockwell C | 11 |

| Hardness, Vickers | 209 |

| Tensile Strength, Ultimate | 344 MPa |

| Tensile Strength, Yield | 275 – 410 MPa |

| Elongation at Break | 20% |

| Tensile Modulus | 105 GPa |

| Compressive Modulus | 110 GPa |

| Poissons Ratio | 0.37 |

| Shear Modulus | 45.0 GPa |

Welding

The weldability of grade 7 Ti-0.15Pd alloy is excellent. Due to Titanium Grade 7 being a single-phase material, the thermal treatments or welding temperatures have no affection on the microstructure of the alpha phase.

Annealing

Mostly, the delivery condition is annealing. The heat treatment of Titanium Grade 7 will be heating to 650-760°C (1202-1400°F) for 6 min -2 h and then cooling in air.

In case some customers require stress-relieved, the heat treatment will be heating the material to 480-595°C (896-1103°F) for 15 min – 4 h, and then cooling in air.

Applications:

Chemical processing and storage – containers, heat exchangers, ducting, pumps, valves, fittings, and auxiliary equipment.

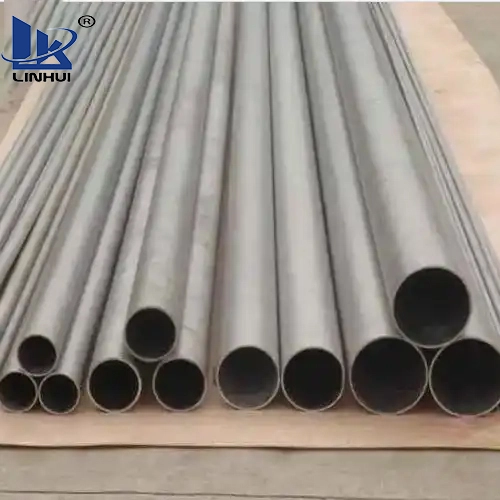

Product Forms:

Sheet/Plate: ASTM B265 Gr7

Heat exchanger/Condenser Tube: ASTM B338 Gr7

Round/Square/Flat Bar: ASTM B348 Gr7

Casting Billets: ASTM B367 Gr7

Forgings: ASTM B381 Gr7

Nuts: ASTM F467 Gr7

Bolts: ASTM F468 Gr7

Shipping & Delivery:

| Packing & Shipping |

1. Accept the request/customized packing | |

2. Normally, goods will packed in poly bags, drawstring bags, carrying bags, and cartons | |

3. For the sample, we will use TNT, Fedex, UPS, DHL, etc to ship it, | |

4. For bulk, it depends on the qty, by air, by train or by sea are all available. |