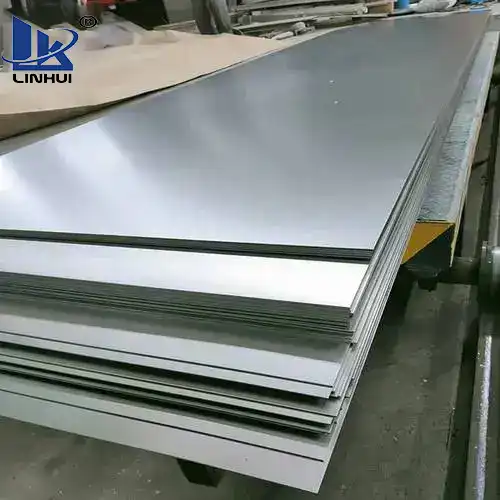

Wholesale Customized Purity 99% Titanium Plates

Specification: Gr1 Gr2 Gr3 Gr5 Gr7 Gr9 Gr12 Gr16 etc.

Width: MAX:300mm

Length: Max 1000mm

Technique: Cold Rolled

Shape: Square

A significant feature of Wholesale Customized Purity 99% Titanium Plates is strong corrosion resistance, this is due to its affinity for oxygen is particularly large, can generate a layer of dense oxide film on its surface, can protect titanium from media corrosion, in acidic, alkaline, neutral saline solution and oxidizing medium has a very good stability, better than the existing stainless steel and other commonly used non-ferrous metals corrosion resistance.

The quality of titanium plate is largely determined by the Wholesale Customized Purity 99% Titanium Plates manufacturer's smelting process, including the chemical composition of titanium, titanium water cleanliness (gases, harmful elements, inclusions) and the quality of the cast billet (compositional segregation, decarburization and its surface condition), which are precisely the key control points of the smelting operation.

Product Information

| Product Name | Wholesale Customized Purity 99% Titanium Plates |

| Specification | Gr1 Gr2 Gr3 Gr5 Gr7 Gr9 Gr12 Gr16 etc. |

| Width | MAX:300mm |

| Length | Max 1000mm |

| Technique | Cold Rolled |

| Shape | Square |

| Transport Package | Standard |

| Density | 4.5g/cm3 |

| Purity | 99.95%min |

| Processing Service | Bending, Welding, Cutting, Punching |

| Application | Aerospace, Weaponry, Energy, Chemical, Metallurgy, Construction and Transportation |

Manufacturing process for titanium plates:

Hot forging: a forging process carried out above the recrystallization temperature of the metal.

Hot rolling: rolling process carried out above the recrystallization temperature.

Cold rolling: plastic deformation temperature below the recovery temperature of the rolling process.

Annealing: the metal is slowly heated to a certain temperature, maintained for a sufficient period of time, and then cooled at a suitable rate (usually slow cooling, sometimes controlled cooling) of a metal heat treatment process.

Pickling: immersing a workpiece in an aqueous solution of sulfuric acid, etc., to remove thin films of oxides, etc., from the surface of the metal. It is a pretreatment or intermediate treatment for electroplating, enameling, rolling and other processes.

Titanium plate characteristics

1. Titanium plate is the surface of the oxidized film is equivalent to a good wear-resistant hair separator, the use of titanium plate saves the separator, so that the pole plate is easy to peel off, eliminating the process of pre-treatment of the plate, titanium plate is lighter than the copper seed plate to half.

2. The service life of titanium plate is more than 3 times than that of copper seed plate, and it can reach 10-20 years according to the operation conditions.

3. Electrolytic copper made from titanium plate has a dense crystalline organization, flat and smooth surface, and excellent quality.

4. Since the Wholesale Customized Purity 99% Titanium Plates do not need to be coated with a separator, it can avoid the pollution of the copper electrolyte.

The surface quality of titanium plate:

1, the surface of the plate should be smooth and clean, in the original color of the metal. The plate is allowed to be supplied with sandblasted surface;

2, the surface of the plate is allowed to exist a slight darkening and local water stains; allowed to have localized, not more than half of the thickness tolerance of the scratches, indentations, pits and other defects, but should be guaranteed to be smaller thickness;

3, the surface of the plate is not allowed to have cracks, skinning, oxidized skin, pressure folding, metal and non-metallic inclusions and other macro-defects and traces of over-alkali washing;

4, the plate is allowed to clear the local defects along the rolling direction, but the thickness of the plate after removal shall not be less than Z small allowable thickness;

5、When there are special requirements on the surface quality of the plates, they can be supplied through negotiation between the supply and demand sides.

FAQ

Can I get some samples?

Yes, we can provide free Wholesale Customized Purity 99% Titanium Plate samples, just pay the shipping cost by yourself.

How do I start an order or make a payment?

Once we receive the purchase order, we will attach a pro forma invoice with our bank information. Wire transfer is available.

What is your minimum order quantity?

For stock, there is no minimum order quantity.

For customized products, the MOQ can be determined according to the actual product.

What is the delivery time?

Spot delivery: 3-5 days from the date of receipt of prepayment.

Customized delivery: 20-25 days after order confirmation.

Is there any discount?

Yes, there are different discounts for different quantities.

How do you deal with quality complaints?

First of all, our quality control reduces quality problems to near zero. If the quality problem is caused by us, we will replace the Wholesale Customized Purity 99% Titanium Plates product or refund your loss for free.