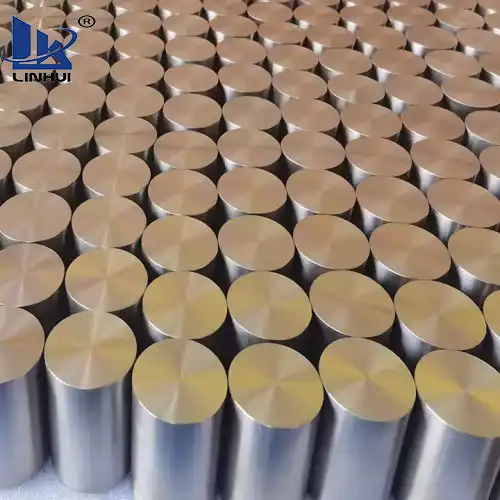

Astm B550 Zirconium Alloy Bars

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

Astm B550 Zirconium Alloy Bars: The Ultimate Solution for Demanding Industries

When it comes to selecting the right material for high-performance applications, Astm B550 Zirconium Alloy Bars offer an unmatched combination of strength, durability, and corrosion resistance. Whether you’re in the aerospace, marine, chemical, or energy sectors, this versatile material is ideal for use in the most demanding environments. With its exceptional properties, the Astm B550 Zirconium Alloy Bars is preferred for engineers and procurement managers worldwide.

Specifications

| Property | Value |

|---|---|

| Material | Zirconium Alloy |

| Standard | ASTM B550 |

| Chemical Composition | Zirconium (Zr), Niobium (Nb), and other trace elements |

| Form | Bar (custom sizes available) |

| Density | 6.51 g/cm³ |

| Tensile Strength | 345 MPa |

| Yield Strength | 250 MPa |

| Elongation | 20% |

| Hardness | 175-220 HV |

| Melting Point | 1855°C |

| Corrosion Resistance | Excellent in saltwater and chemical environments |

Why Choose Us as Your Supplier of Astm B550 Zirconium Alloy Bars?

At Linhui Titanium, we specialize in providing high-quality materials for the most challenging applications. Our dedication to customer satisfaction, product quality, and timely delivery makes us a preferred partner for many industries. Here’s why you should choose us as your supplier of Astm B550 Zirconium Alloy Bars:

- Industry-Leading Quality: Our products undergo stringent quality checks to ensure compliance with international standards, including ASTM B550.

- Global Logistics & Packaging: We provide reliable global shipping with secure packaging to ensure your products arrive in perfect condition.

- Custom Solutions: We offer custom-sized zirconium alloy bars to meet your specific project requirements.

- Expert Team: Our team of experienced engineers and customer service professionals are ready to assist you with any queries or technical support.

- Sustainability: We are committed to environmental responsibility through sustainable practices in our manufacturing processes.

Production Process

The Astm B550 Zirconium Alloy Bars is manufactured using cutting-edge technology and high-precision equipment to ensure exceptional quality. Our process includes:

- Melting: We start with high-purity zirconium and carefully melt the material under controlled conditions to create the alloy.

- Forming: The molten material is then formed into bars through a combination of forging and rolling techniques.

- Heat Treatment: We apply heat treatment to optimize the material’s mechanical properties, such as tensile strength and ductility.

- Quality Control: Each batch undergoes comprehensive testing to ensure that it meets ASTM B550 standards and is ready for industrial applications.

Product Advantages and Characteristics

- Corrosion Resistance: Zirconium alloys are known for their excellent resistance to corrosion in both acidic and alkaline environments. They are particularly resistant to saltwater, making them perfect for marine and offshore applications.

- High Strength and Durability: Astm B550 Zirconium Alloy Bars offer superior strength, ensuring they can withstand the most demanding applications in aerospace, energy, and petrochemical industries.

- Lightweight: Unlike many other metals, zirconium is lightweight yet maintains a high strength-to-weight ratio, making it ideal for industries like aerospace and high-performance automotive.

- Biocompatibility: Zirconium alloys are non-toxic and biocompatible, making them suitable for use in medical applications.

Application Areas

Astm B550 Zirconium Alloy Bars are widely used in various industries, including:

- Aerospace & Defense: For components like aircraft parts, rocket nozzles, and military equipment that require exceptional strength-to-weight ratios and high-temperature resistance.

- Marine & Offshore: Due to their corrosion resistance, zirconium alloy bars are used in ships, submarines, and offshore oil rigs exposed to harsh seawater conditions.

- Chemical & Petrochemical: In chemical reactors, heat exchangers, and pipelines, where resistance to corrosive substances is critical.

- Energy: These alloy bars are crucial in high-performance equipment for oil and gas pipelines, reactors, and power generation machinery.

- Medical Equipment: Zirconium alloys are used in surgical implants, diagnostic devices, and other medical equipment that requires biocompatibility and high-performance material.

- Automotive: For high-performance automotive parts where weight reduction and strength are necessary.

Our Factory

Linhui Titanium operates a state-of-the-art factory located in the heart of China’s titanium industry. We are equipped with the latest technologies and adhere to strict quality standards to produce premium Astm B550 Zirconium Alloy Bars products. With over 20 years of experience, we are a leader in the titanium and zirconium industries, offering products that meet global standards.

Certifications

We are proud to hold numerous certifications, ensuring our products meet the highest standards of quality and safety:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- OHSAS 18001:2007 Occupational Health & Safety

- TÜV Nord AD2000-W0 Certification

- PED 2014/68/EU Certification

- ABS, DNV, BV, CCS, GL, and many others

These certifications guarantee that our Astm B550 Zirconium Alloy Bars are manufactured to meet the rigorous standards required for industrial applications.

Frequently Asked Questions (FAQs)

Q1: What is the lead time for Astm B550 Zirconium Alloy Bars?

A1: Lead time varies depending on order volume and customization. Typically, it ranges from 2 to 4 weeks.

Q2: Can you provide custom sizes for zirconium alloy bars?

A2: Yes, we offer customization options for specific sizes to meet your project needs.

Q3: Are the zirconium alloy bars compatible with high-temperature applications?

A3: Yes, zirconium alloys are ideal for high-temperature environments due to their excellent thermal stability.

Q4: What certifications do you have for quality assurance?

A4: We hold ISO 9001, ISO 14001, OHSAS 18001, and several other industry-standard certifications.

Contact Us

For more information about our Astm B550 Zirconium Alloy Bars, or to request a quote, please feel free to contact us:

- Email: linhui@lhtitanium.com