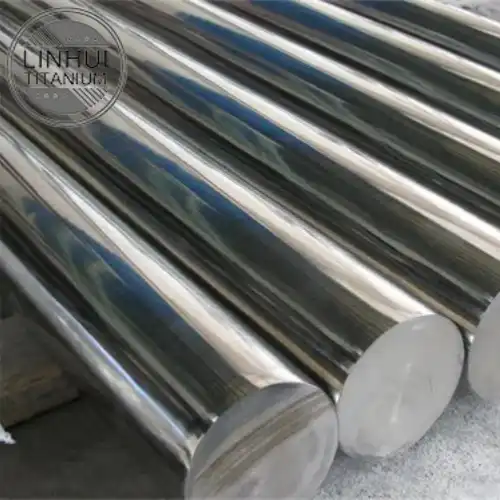

zirconium rod

Product name: Zirconium rod

Specifications (mm):φ3mm-φ300mm

Condition: forged rod, rolled rod, polished rod

Brand: ZR702, ZR1 high purity zirconium 99.99%

Implementation standards: ASTM B550 ASTM B551 GB/T21183-2007

Product name: Zirconium rod

Specifications (mm):φ3mm-φ300mm

Condition: forged rod, rolled rod, polished rod

Brand: ZR702, ZR1 high purity zirconium 99.99%

Implementation standards: ASTM B550 ASTM B551 GB/T21183-2007

Zirconium has a wide range of applications. Metal zirconium only accounts for about 3% to 4%. It is mainly used in ceramics, refractory materials, and other fields in the form of zirconium silicate and zirconium oxide. This part of the application accounts for more than 90% of zirconium consumption. In addition, due to the excellent nuclear properties of metallic zirconium, its thermal neutron absorption cross-section is small, only 0.18×10-28. An important use of zirconium and its alloys is as fuel cladding materials and other structural materials for nuclear power reactors. Therefore, the research and development of zirconium and zirconium alloys are closely related to the development of the nuclear industry. They were initially used in nuclear-powered ships and later in the development of atomic power plants.

Physical and chemical properties of zirconium rods

physical properties

Zirconium rods have good mechanical properties and are characterized by high strength, high toughness, and corrosion resistance.

The density of zirconium rods is relatively high, with a value of approximately 6.5 g/cm, which is close to the density of steel.

The melting point of the zirconium rod is relatively high, about 1852C, allowing it to work stably in high-temperature environments.

Zirconium rods have good thermal conductivity and can effectively dissipate heat.

chemical properties

Zirconium rods have good corrosion resistance and can withstand corrosion from a variety of strong acids, strong alkalis, and most organic solvents.

Zirconium rods have low electrochemical activity and therefore have excellent corrosion resistance. The surface of zirconium rods is usually oxidized to increase its corrosion resistance and stability

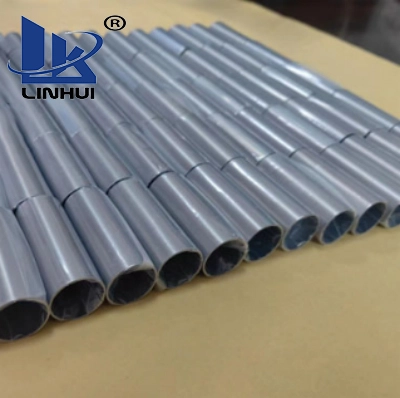

Zirconium rod production process

Raw material preparation

1. Choose high-purity zirconium ore as raw material.

2. Crush and grind zirconium ore to obtain fine ore particles.

Smelting and casting

1. Mix zirconium ore with other metal elements in a certain proportion and put them into an electric furnace for smelting.

2. Pour the molten alloy into the pre-prepared casting mold, and after cooling and solidification, the preliminary zirconium rod material is obtained.

Thermal processing and finishing

1. Thermal processing of zirconium rod bad materials, including hot rolling, hot extrusion and other processes, to improve its density and mechanical properties.

2. Carry out finishing, including cold rolling, cold drawing and other processes to obtain higher precision and better surface quality