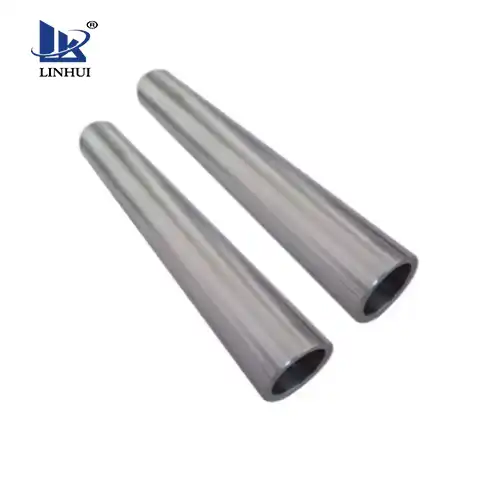

Zirconium Seamless Tubes

Zirconium brand:ZR60702 ZR60705

Zirconium standard:ASTM B658,GB / 26283

Processing: Rolled Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Zirconium Seamless Tubes: High-Performance Solutions for Critical Industries

Zirconium Seamless Tubes are essential components for various high-performance applications, particularly in industries requiring exceptional corrosion resistance and durability. At LINKUN TITANIUM, we provide zirconium seamless tubes that meet the rigorous demands of sectors like aerospace, chemical processing, marine, and energy. Our products are engineered to deliver unmatched quality, ensuring longevity and performance in even the most challenging environments.

Specifications

| Parameter | Details |

|---|---|

| Material | Zirconium (Zr) |

| Tube Type | Seamless |

| Outer Diameter Range | 6mm to 200mm |

| Wall Thickness | 0.5mm to 15mm |

| Length | Customizable |

| Grade | Zr-702, Zr-705, Zr-4 |

| Standard | ASTM B551, ASTM B338 |

| Surface Finish | Polished, Annealed |

| Tensile Strength | 345 MPa (Grade 705) |

| Corrosion Resistance | Excellent in acid and alkali environments |

| Applications | Aerospace, Chemical, Marine, Energy |

Why Choose Us as Your Zirconium Seamless Tubes Supplier?

At LINKUN TITANIUM, we stand out as the premier supplier of Zirconium Seamless Tubes due to our commitment to quality, customer satisfaction, and industry leadership. Here’s why you should choose us:

- Superior Product Quality: Our zirconium tubes undergo rigorous testing and quality control to ensure they meet international standards like ASTM B551 and B338.

- Global Logistics: With a strong export network, we deliver our products to over 60 countries, ensuring timely and secure delivery no matter your location.

- State-of-the-Art Packaging: We pack our products with precision to prevent damage during transport, ensuring they reach you in perfect condition.

- Experienced Team: Our highly skilled professionals bring decades of experience in the titanium and zirconium industry, ensuring the highest level of expertise in both production and customer service.

- Custom Solutions: We offer customized zirconium seamless tubes in various dimensions and grades to meet your specific project needs.

Production Process

Our Zirconium Seamless Tubes are manufactured using advanced techniques to ensure high strength and superior corrosion resistance. The production process includes:

- Raw Material Selection: We carefully select high-quality zirconium alloys to ensure the best material properties.

- Extrusion and Tube Formation: The selected alloy is extruded into seamless tubes, ensuring uniformity in wall thickness and strength.

- Heat Treatment: The tubes undergo a controlled heat treatment process to enhance their mechanical properties and corrosion resistance.

- Finishing: After heat treatment, the tubes are polished and annealed to achieve the desired surface finish.

- Quality Testing: Each batch of zirconium tubes is subjected to extensive testing, including tensile strength, corrosion resistance, and dimensional checks.

Product Advantages and Characteristics

- Exceptional Corrosion Resistance: Zirconium’s natural ability to withstand corrosion makes it ideal for applications in highly corrosive environments, such as chemical reactors and marine structures.

- High-Strength-to-Weight Ratio: zirconium seamless tubes offer an excellent combination of strength and lightweight properties, making them ideal for aerospace and high-performance automotive applications.

- Biocompatibility: Zirconium’s biocompatibility makes it suitable for medical applications, ensuring safety and durability in sensitive environments.

- Thermal Stability: Our zirconium tubes maintain their performance even under high temperatures, making them an excellent choice for industries like power generation and aerospace.

Application Areas

Zirconium Seamless Tubes are used across various industries, including:

- Aerospace and Defense: For aircraft components and military applications requiring high strength and resistance to extreme conditions.

- Chemical and Petrochemical: In chemical processing equipment like reactors, heat exchangers, and pipelines that need to withstand aggressive environments.

- Marine and Offshore: For shipbuilding, submarines, and offshore structures exposed to saltwater corrosion.

- Energy: In power plants, oil and gas pipelines, reactors, and other energy sector equipment where reliability and long-term performance are crucial.

- Medical Equipment: In surgical instruments, diagnostic machines, and implants due to their non-reactivity and strength.

Our Factory

LINKUN TITANIUM operates a modern, cutting-edge manufacturing facility that is a leader in the titanium and zirconium industries. We are committed to providing our global customers with high-performance materials. Our factory is equipped with state-of-the-art technology and adheres to the highest international standards to ensure top-quality zirconium seamless tubes products.

Certifications

We proudly hold various certifications that demonstrate our commitment to quality and compliance with global standards, including:

- ISO 9001:2015 Quality Management System

- PED 2014/68/EU

- TUV Nord AD2000-W0 Certification

- ISO 14001:2015 Environmental Management

- OHSAS 18001:2007 Occupational Health and Safety

- Third-party Inspections: Our products are regularly inspected by leading agencies such as SGS, BV, DNV, and TUV to ensure the highest quality and compliance.

Frequently Asked Questions

-

What are the advantages of Zirconium over other materials? Zirconium offers excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for critical applications in harsh environments.

-

How do I place an order for Zirconium Seamless Tubes? Simply contact us and our team will guide you through the ordering process, including product customization and shipping arrangements.

-

Can you provide custom dimensions and grades? Yes, we offer customized zirconium seamless tubes based on your specific requirements, including custom dimensions and alloy grades.

Contact Us

For more information or to request a quote, feel free to get in touch with our team. We are here to assist you with all your zirconium seamless tubes needs.

Email: linhui@lhtitanium.com