As a professional in the field of heat transfer systems, I understand the critical role that material selection plays in achieving optimal efficiency. Among the various materials available, GR2 titanium emerges as a top choice for heat exchanger applications due to its remarkable properties and performance advantages.

Introduction to Heat Exchanger Systems:

Before delving into the specifics of GR2 titanium pipes, let's briefly explore the significance of heat exchanger systems. These systems are integral to various industrial processes, including power generation, chemical processing, HVAC (heating, ventilation, and air conditioning), and more. The primary function of a heat exchanger is to transfer heat from one fluid to another while keeping them physically separated. This process is crucial for maintaining desired temperatures, enhancing energy efficiency, and ensuring the smooth operation of industrial processes.

The Role of Material Selection:

The efficiency and reliability of a heat exchanger heavily depend on the materials used in its construction. Factors such as thermal conductivity, corrosion resistance, mechanical strength, and cost-effectiveness must be carefully considered when selecting materials. Among the wide array of options, titanium stands out as a superior choice, particularly grade 2 titanium (GR2), owing to its exceptional properties.

Properties of GR2 Titanium:

GR2 titanium is a commercially pure grade of titanium characterized by its high corrosion resistance, excellent weldability, and impressive strength-to-weight ratio. These properties make it an ideal material for applications where durability, longevity, and efficiency are paramount. Additionally, titanium exhibits superb thermal conductivity, allowing for efficient heat transfer across the surface of heat exchanger components.

Enhanced Heat Transfer Efficiency:

One of the key advantages of using GR2 titanium pipes in heat exchanger systems is their ability to facilitate superior heat transfer. The high thermal conductivity of titanium ensures rapid and uniform distribution of heat, resulting in enhanced efficiency and performance of the overall system. This translates to reduced energy consumption, lower operating costs, and improved productivity in industrial processes.

Corrosion Resistance:

Corrosion is a significant concern in many industrial environments, particularly those involving exposure to aggressive chemicals or high temperatures. GR2 titanium boasts exceptional corrosion resistance, even in harsh operating conditions, making it highly suitable for use in corrosive environments. This inherent resistance to corrosion ensures the longevity and reliability of heat exchanger systems, minimizing downtime and maintenance costs.

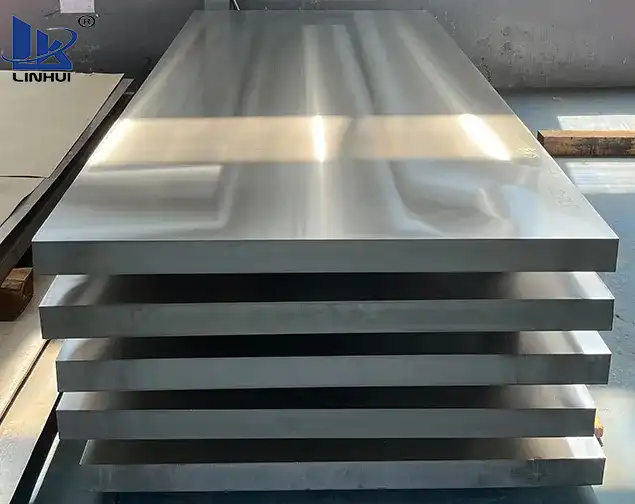

Mechanical Strength and Durability:

In addition to its corrosion resistance, GR2 titanium exhibits impressive mechanical strength and durability. This allows heat exchanger components such as pipes, tubes, and plates to withstand high pressures and temperatures without compromising their structural integrity. As a result, GR2 titanium heat exchangers offer long-term reliability and performance, providing peace of mind to operators and engineers alike.

Cost-Effectiveness:

While titanium may have a higher initial cost compared to some other materials, its long-term benefits far outweigh the initial investment. The extended lifespan, reduced maintenance requirements, and enhanced efficiency of GR2 titanium heat exchangers result in significant cost savings over the lifetime of the system. Moreover, the inherent recyclability of titanium further contributes to its overall sustainability and cost-effectiveness.

Conclusion:

In conclusion, the choice of material plays a crucial role in determining the efficiency, reliability, and longevity of heat exchanger systems. GR2 titanium emerges as a superior option for achieving optimal heat transfer efficiency, thanks to its exceptional properties such as high thermal conductivity, corrosion resistance, mechanical strength, and durability. By investing in GR2 titanium pipes for your heat exchanger system, you can ensure maximum performance, minimal downtime, and long-term cost savings.

Contact Us for More Information:

If you want to learn more about GR2 titanium pipes for heat exchangers, please feel free to contact us at linhui@lhtitanium.com.

This article has been written to provide professional insights to buyers and global dealers interested in optimizing their heat transfer systems with GR2 titanium.

References:

1. ASTM International. (n.d.). ASTM B861 / B861M - 19 Standard Specification for Titanium and Titanium Alloy Seamless Pipe. https://www.astm.org/Standards/B861.htm

2. Glinka, G. (2001). Titanium and titanium alloys as construction materials for industrial equipment. Materials Science, 37(1), 1-16.

3. Xu, W., & Sun, X. (2017). Recent progress in titanium heat exchangers. Materials Science and Engineering: A, 689, 1-18.