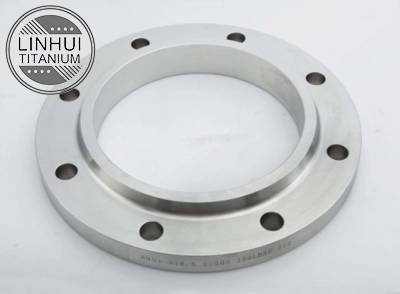

Astm B381 Grade 2 Pure Titanium Forged Ring Forging

Specifications : ASTM B381 / ASME SB381

Standard : ANSI / ASME B16.5

Size : 1/8" NB to 48" NB

Thickness : 40-400mm

Size: Outer Diameter: 200-1300mm,Inner Diameter: 100-900mm,Height: 35-250mm

Material: Titanium and titanium alloys

Two Factories & 30 titanium metal production lines

21 years of experience in titanium metal manufacturing

Systerm quality with ISO / SGS / TUV quality control.

Delivery term: DHL, FEDEX, Air freight,Sea freight

Annual production: 800 tons

ASTM B381 Grade 2 Pure Titanium Forged Ring Forging Product Page

Introduction

Welcome to LINKUN TITANIUM! As a leading provider of premium-grade titanium products, we are proud to offer the ASTM B381 Grade 2 Pure Titanium Forged Ring Forging. This product stands out for its exceptional strength, corrosion resistance, and lightweight properties, making it the ideal choice for industries that demand high-performance solutions. Whether you're in aerospace, marine, chemical, or energy sectors, our titanium forged rings offer unmatched reliability and durability.

Specifications

Below are the detailed specifications of our ASTM B381 Grade 2 Pure Titanium Forged Ring Forging:

| Specification | Description |

|---|---|

| Standard | ASTM B381 / ASME SB381 |

| Size | 1/8" NB to 48" NB |

| Thickness | 40-400mm |

| Outer Diameter | 200-1300mm |

| Inner Diameter | 100-900mm |

| Height | 35-250mm |

| Material | Titanium and titanium alloys |

| Delivery Options | DHL, FEDEX, Air Freight, Sea Freight |

Why Choose Us as Your Supplier

Our Advantages

- Expertise: With over 21 years of experience, LINKUN TITANIUM has become a trusted name in titanium manufacturing, serving over 60 countries and regions.

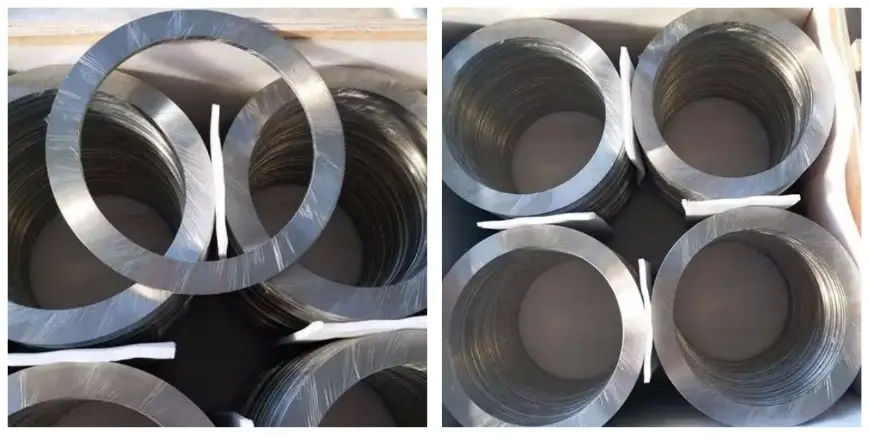

- State-of-the-Art Production: Our two factories and 30 titanium production lines ensure consistent quality and high-volume capabilities, with an annual production capacity of 800 tons.

- Superior Quality: We adhere to strict quality control systems, holding ISO, SGS, and TUV certifications to guarantee that every forged ring meets your standards.

- Fast and Reliable Logistics: We provide flexible shipping options, including DHL, FEDEX, air freight, and sea freight, ensuring prompt and secure delivery.

Our Service

- Personalized Customer Support: Our dedicated team is ready to assist with custom specifications, order queries, and post-purchase support.

- OEM Services: We offer OEM services to cater to your specific requirements and designs.

Production Process

- Material Selection: We source premium-grade titanium billets to ensure superior forging quality.

- Heating and Forging: Our state-of-the-art forging process, carried out under controlled conditions, ensures consistent shape and mechanical properties.

- Machining and Inspection: Each ring undergoes precision machining and rigorous inspections to meet Astm B381 Grade 2 Pure Titanium Forged Ring Forging standards.

- Final Finishing: Our finishing process ensures a smooth surface and optimal dimensional accuracy.

Product Advantages and Characteristics

- Corrosion Resistance: Exceptional resistance to chemical, saltwater, and acidic environments.

- High Strength-to-Weight Ratio: Strong yet lightweight, perfect for applications requiring both durability and weight reduction.

- Temperature Resistance: Suitable for high-pressure and high-temperature environments.

- Biocompatibility: Non-toxic and hypoallergenic, ideal for medical applications.

Application Areas

- Aerospace & Defense: Components for aircraft and military equipment.

- Marine & Offshore: Used in ships, submarines, and offshore structures.

- Chemical & Petrochemical: Equipment for handling aggressive chemicals and high temperatures.

- Energy (Oil & Gas, Power Generation): Pipelines, reactors, and other stress-intensive equipment.

- Medical Equipment: Ideal for surgical and diagnostic tools.

- High-Performance Automotive: Lightweight, high-strength parts for racing vehicles.

Our Factory

Linhui operates modern, state-of-the-art facilities dedicated to titanium production. Our commitment to quality and innovation keeps us at the forefront of the titanium industry. We ensure consistent quality control and maintain a customer-focused approach to deliver high-performance products worldwide.

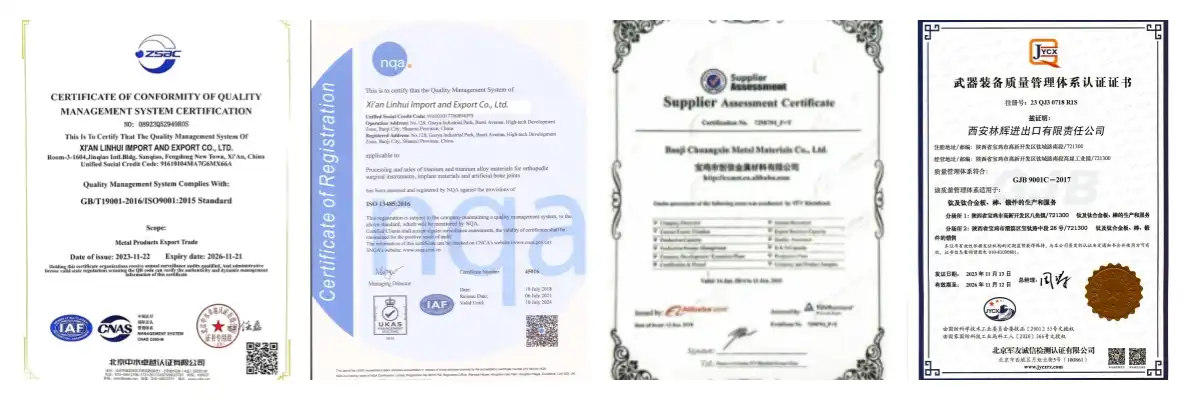

Certification

We hold several certifications to guarantee the highest standards:

- Manufacturing License of Special Equipment (China)

- TUV Nord AD2000-W0 Certification

- PED 2014/68/EU Certification

- CCS, ABS, DNV, BV, BSI, LLOYD'S, GL Certification

- ISO 9001:2015 QMS Certificate

- OHSAS 18001:2007 Certificate

- ISO 14001:2015 Certificate

We are also approved by renowned third-party inspection agencies, including DNV, BV, SGS, Moody's, and more.

Frequently Asked Questions (FAQs)

1. What is the lead time for orders?

Typically, our lead time is between 2 to 6 weeks, depending on order specifications and volume.

2. Can you provide custom sizes and specifications?

Yes, we offer custom dimensions and OEM services to meet your exact needs.

3. What shipping options do you offer?

We provide flexible shipping options, including DHL, FEDEX, air freight, and sea freight.

4. Are your products certified?

Yes, all our products meet international standards and come with relevant certifications.

Contact Us

Ready to place an order or have more questions? Contact us at linhui@lhtitanium.com for personalized support and Astm B381 Grade 2 Pure Titanium Forged Ring Forging inquiries. Our team is here to assist!