Titanium fastener

Size: M1.6-M60mm

Standard: DIN934,DIN,JIS...

Application: Automotive, aerospace, electronics, medical, etc.

Technique: cnc machining, hot rolled

Material: Titanium

Surface: Bright

Certification:ISO,EN10204 3.1,EN10204 3.2

Shape: as the customer request shape-cutting

Titanium Fasteners: Ideal for Lightweight, High Strength and Corrosion Resistance

Titanium fasteners are preferred in high-end fields such as aerospace, medical devices, chemical and marine engineering due to their light weight, high strength and excellent corrosion resistance.

What is titanium fastener?

Titanium fasteners are connectors made of titanium or titanium alloys, including bolts, nuts, screws, washers, and so on. Its main features include:

- Lightweight: the density of titanium is only 60% of steel, but the strength is comparable.

- High strength: titanium fasteners have excellent mechanical properties for high load applications.

- Corrosion resistance: excellent performance in acidic, alkaline and chloride environments for extended service life.

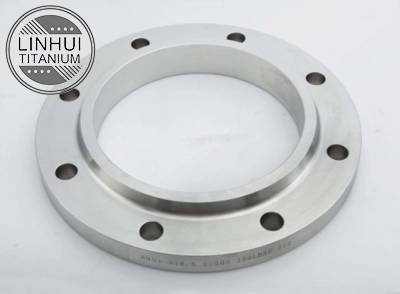

Product Information

| Product Name | Titanium fastener |

| Size | M1.6-M60mm |

| Standard | DIN934, DIN, JIS... |

| Application | Automotive, aerospace, electronics, medical, etc. |

| Technique | cnc machining, hot rolled |

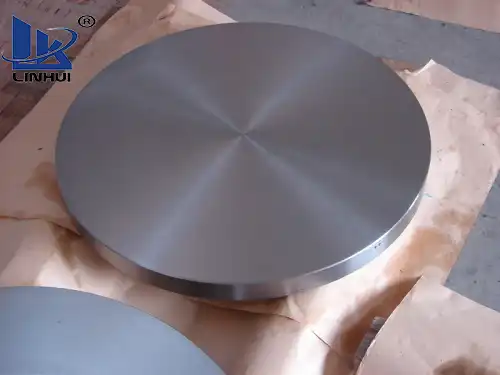

| Material | Titanium |

| Surface | Bright |

| Certification | ISO,EN10204 3.1,EN10204 3.2 |

| Shape |

as the customer requested shape-cutting |

Material properties of titanium fasteners

- Lightweight Design

Titanium's low density significantly reduces equipment weight for the aerospace and automotive industries.

- High strength and durability

Tensile strength: ≥900 MPa

Yield strength: ≥830 MPa

Elongation: ≥ 10%

- Corrosion resistance

Excellent performance in seawater, acidic and high temperature environments, suitable for chemical and marine engineering.

- Biocompatibility

Non-toxic, non-magnetic, suitable for medical device and implant applications.

Our Factory

Contact us now for exclusive offers!

Purchase titanium fasteners now and receive the following discounts:

DISCOUNT OFFER: Special 5% discount for first time buyers.

Free samples: Free samples are provided for your testing and verification.

Technical Support: Free technical consultation and material selection suggestions. Emai:linhui@lhtitanium.com